Choosing the right mechanical fixture is crucial for project success. According to a recent report by IndustryWeek, 70% of manufacturing issues stem from inadequate fixtures. These tools significantly enhance productivity and precision. When selecting a mechanical fixture, consider both material and design.

Expert Dr. John Smith emphasizes, "The fixture's quality directly impacts assembly speed and accuracy." His words resonate in the industry, highlighting how a well-designed fixture saves time and reduces errors. However, many firms overlook their fixture choices, leading to costly mistakes.

It's essential to evaluate your project's specific needs. Not all fixtures fit every application. Investing time in research can prevent pitfalls. Remember, a mechanical fixture is not just a tool; it's a vital component of your success.

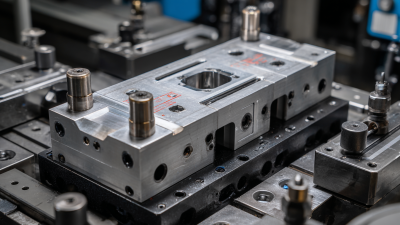

Mechanical fixtures play a crucial role in engineering projects. They provide stability and support during manufacturing processes. This stability is essential for achieving precise measurements and high-quality products. For instance, during welding, a fixture secures components in place. This prevents movement and ensures accurate alignment.

Understanding the purpose of these fixtures helps in selection. Different projects require different types. Consideration of material, weight, and type of operation is vital. A fixture for machining may differ greatly from one used for assembly. Reflecting on past projects might reveal mistakes in choosing fixtures. These errors can lead to delays and additional costs.

Another factor to think about is adjustability. Some projects demand flexibility. However, overly complex fixtures can create confusion. Keeping designs simple is often more effective. It might be tempting to go for advanced solutions, but they can complicate the process unnecessarily. Balancing simplicity with functionality is crucial for success.

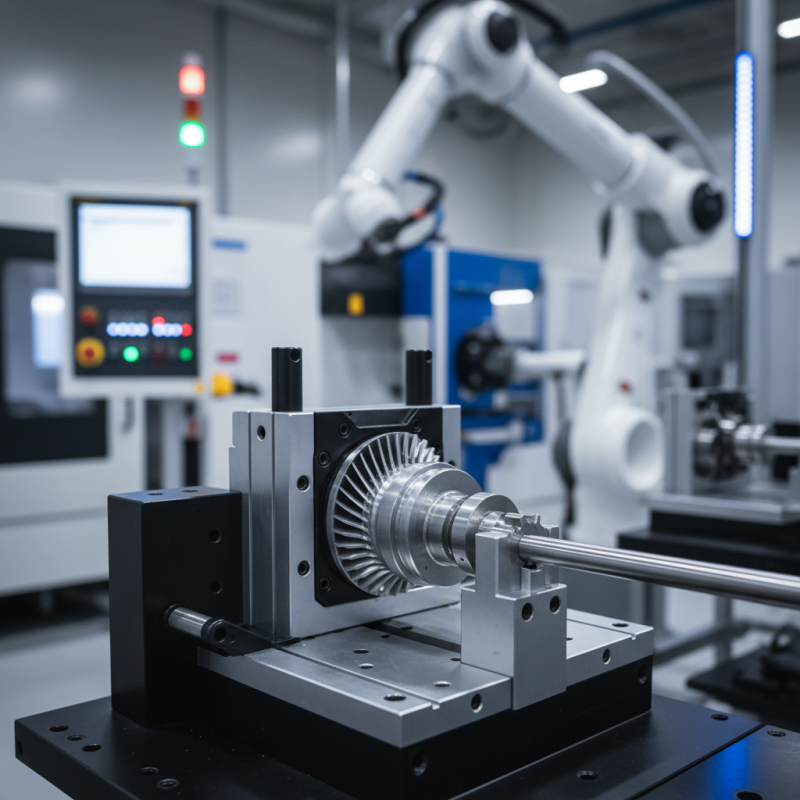

When selecting a mechanical fixture, understanding your project's specific needs is crucial. You need to consider factors like material type, load capacity, and precision requirements. Identify the parts you will be working with. How complex is the assembly? Understand if your fixture should allow for adjustments.

Tip: Map out your workflow. Visualize how components interact. This will help you identify where precision is critical. It’s easy to overlook details but doing so can lead to inefficiencies later.

Consider the environment too. Will your fixture face extreme conditions? Think about temperature, humidity, or exposure to chemicals. These factors influence your choice significantly.

Tip: Gather feedback from your team. They may provide insights you haven’t considered. Sometimes, reliance on experience leads to assumptions that might not hold. Reflect on the requirements you may have missed. The right choice will align with both current and future needs.

This chart illustrates the importance levels of various key requirements for selecting a mechanical fixture in a project. Each requirement is rated on a scale from 1 to 10 based on its significance to the project needs.

Choosing the right mechanical fixture is crucial for any project. Different types of fixtures serve unique purposes. For instance, welding jigs help maintain precise angles during the welding process. They reduce the risk of errors, but they can be complex to set up correctly.

Another common type is the assembly fixture. These tools align and support components as they are put together. The design must be flexible. It should accommodate variations in parts. Not all assembly fixtures can handle multiple designs equally well.

Drilling fixtures are also noteworthy. They guide drill bits to specific locations. This increases accuracy in machining operations. However, if the fixture is not adjustable, it may lead to limitations in versatility. Each fixture type has its strengths and weaknesses, and the right choice depends on your project's unique requirements. Being aware of these factors can lead to better outcomes.

When selecting a mechanical fixture, the choice of materials plays a crucial role in durability and performance. Different materials offer distinct advantages and disadvantages. For instance, metals like aluminum can be lightweight yet strong, making them suitable for applications requiring precision. On the other hand, steel provides excellent strength but may add unwanted weight. Choosing the right balance is essential.

Consider environmental factors too. Will the fixture face high temperatures or corrosive substances? In these cases, materials like stainless steel or specialized plastics may be more appropriate. Reflect on the specific needs of your project and its environment. A short lifespan can lead to increased costs and downtime.

Looking at performance, how well does the material withstand stress and strain? Test prototypes when possible. Some materials may sound good on paper but perform poorly in real-life conditions. Observe and learn from past projects. Each mistake holds valuable lessons that can guide your current choices.

When selecting a mechanical fixture, budget should be a top priority. A well-planned budget can guide your decision-making process. You might think the cheapest option is the best. However, low-cost fixtures can lack durability. This could lead to higher costs in the long run. Consider the materials used; stronger materials often come with a higher price tag but save money over time.

Analyze the intended use of the fixture. Will it be used for heavy-duty projects or lighter ones? Choosing a fixture that doesn’t match the application can be wasteful. Evaluate the expected lifespan. Some fixtures might seem cheap at first glance but may not last. Look into maintenance costs as well. Neglecting these aspects can lead to frustration and unplanned expenses. A thoughtful approach can lead to better choices.

You might also want to compare different suppliers. Some may offer similar products at various prices. Talk to peers for recommendations. Getting feedback can aid in making a more informed choice. Be willing to adjust your expectations based on what you learn. Remember that the “best” fixture isn’t always the cheapest or the most expensive. It's about finding the right balance.