When embarking on any project, selecting the right tools is crucial for achieving success, particularly when it comes to fixture tools. These specialized instruments are designed to ensure precision and efficiency in various manufacturing and construction tasks. Understanding the different types of fixture tools available can greatly enhance workflow and accuracy, minimizing errors and reducing the overall duration of projects. From clamping and supporting components to ensuring they are securely positioned during fabrication, the right fixture tools can make a significant difference. In this guide, we will explore the various types of fixture tools, their applications, and tips for selecting the most suitable ones for your specific project needs, paving the way for a successful outcome.

When embarking on a project, understanding your specific requirements and goals is crucial in choosing the right fixture tools. Begin by clearly defining what you aim to achieve with your project. Consider the scope, the materials involved, and the complexity of the tasks at hand. For instance, if your project requires precision and repeatability, investing in high-quality, specialized fixtures may be necessary. Assessing your project’s timeline and budget constraints will also guide you in selecting tools that not only meet quality expectations but are also financially viable.

Additionally, it is important to evaluate the versatility and compatibility of the tools with your existing workflow. Opt for fixtures that can accommodate various applications, maximizing their utility across different parts of your project. Engaging with team members and stakeholders to gather insights can further enhance your understanding of project needs. By prioritizing your project's requirements and goals, you can make informed decisions that will ultimately lead to successful outcomes and enhanced efficiency throughout the project lifecycle.

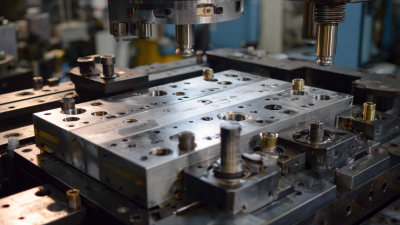

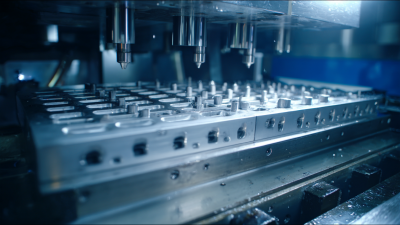

When embarking on any project that involves precision and stability, selecting the right fixture tools is crucial. Fixture tools come in various forms, each tailored for specific applications. Common types include workholding fixtures, assembly fixtures, and welding fixtures. According to a report by Market Research Future, the global market for fixture tools is expected to grow at a CAGR of 5.2%, driven by advancements in manufacturing technologies and increased demand for automation. This underscores the importance of understanding the different types of fixtures available.

Workholding fixtures, designed to securely hold workpieces in place during machining, are essential in industries like aerospace and automotive. Assembly fixtures, on the other hand, ensure components fit together accurately and consistently, which is critical in mass production environments. Welding fixtures provide stability and alignment during the welding process, reducing the risk of defects. The adoption of specialized fixtures can not only enhance efficiency but also minimize rework and improve overall project success, highlighting the necessity of making informed choices in fixture selection.

When embarking on a project, the right fixture tools can make all the difference, especially when you focus on evaluating their quality and durability. Tools constructed from high-grade materials, such as premium steel or aluminum alloys, typically exhibit better performance and longevity. According to a 2021 industry report by the National Association of Manufacturers, utilizing top-quality tools can extend their lifespan by up to 40%, resulting in fewer replacements and lower operational costs over time.

Tips: Always check the material specifications before making a purchase. Additionally, look for tools that come with warranties; they often indicate manufacturers' confidence in the product's durability.

To further ensure that you're selecting reliable fixture tools, consider factors like precision and user reviews. A study from Tooling and Manufacturing Association revealed that tools rated highly for precision can enhance productivity by up to 30%. Implementing thorough research through user feedback can also steer you towards tools that have stood the test of time in various applications.

Tips: Read customer reviews and seek testimonials from industry peers to gauge the reliability of specific tools. Investing time in this research can ultimately lead to significant cost savings and enhanced project outcomes.

When choosing fixture tools for a project, it’s crucial to assess their compatibility with existing equipment. This step not only ensures operational efficiency but also minimizes the risk of costly errors. For instance, in precision agriculture, technologies like GPS and automation need to seamlessly integrate with current farming practices. If the chosen tools are incompatible, they may hinder the efficiencies that modern technology offers, ultimately affecting productivity.

Similarly, in fields such as material science and engineering, innovations like waste polymer recycling systems must be evaluated for their compatibility with existing asphalt binders. Utilizing advanced molecular representation models can provide insights into how new materials will perform alongside established ones. As industries evolve, whether in agriculture or construction, ensuring compatibility not only supports project success but also fosters innovation by enabling the integration of new technologies with the legacy systems that are already in place.

When selecting fixture tools for your project, budgeting and cost considerations play a pivotal role in ensuring successful outcomes. A well-defined budget can help guide your choice of tools, balancing quality and affordability to avoid overspending. It is important to conduct thorough research on the various options available in the market, taking into account not only the initial costs but also the long-term investment in durability and performance. High-quality tools may have a higher upfront cost, but they often translate to higher efficiency and lower maintenance costs in the long run.

Additionally, analyzing the specific needs of your project can help streamline the budgeting process. Consider the complexity of the tasks at hand and the expected frequency of use for the tools. For instance, if the project demands precision and durability, investing in specialized fixture tools might be more cost-effective than using lower-priced, general-purpose options that could compromise the quality of the final output. By aligning your budget with the project’s requirements, you can make informed decisions that not only keep costs in check but also enhance the overall success of your project.