In the ever-evolving landscape of modern manufacturing, the quest for efficiency has become paramount, with advanced tools playing a crucial role in driving productivity. Among these innovations, Fixture Tools have emerged as essential components that significantly enhance operational effectiveness. According to a recent McKinsey report, manufacturers that integrate optimized tooling solutions have experienced productivity boosts of up to 25%, a figure that underscores the criticality of leveraging technology in production processes. Furthermore, a study by the National Institute of Standards and Technology found that streamlined manufacturing practices can lead to a 30% reduction in waste and downtime. By strategically implementing Fixture Tools, companies not only optimize their workflows but also position themselves to meet the growing demands of the competitive market, ultimately paving the way for sustainable growth and profitability.

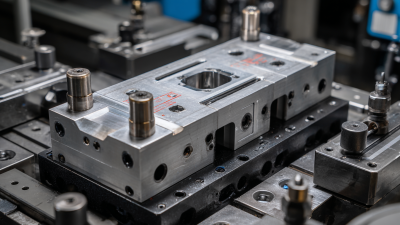

Fixture tools are critical components in modern manufacturing that significantly enhance operational efficiency. By providing stability and precision during the assembly and production processes, these tools minimize the risk of errors and reduce the time spent on setup. When operators can quickly and confidently secure materials and components, they can maintain a steady workflow, eliminating costly downtime. This streamlined approach directly contributes to increased productivity, as manufacturers can produce more in less time.

Moreover, the role of fixture tools extends beyond mere support; they are integral to ensuring product quality. High-quality fixtures allow for consistent and repeatable processes, reducing variability in production outcomes. This uniformity not only boosts productivity but also enhances the overall reliability of manufactured products. As industries strive for lean manufacturing practices, the implementation of efficient fixture tools is becoming more prevalent, showcasing their importance in driving competitive advantage in the rapidly evolving manufacturing landscape.

In modern manufacturing, fixture tools play a pivotal role in enhancing productivity, with reports indicating that they can boost efficiency by up to 25%. One of the key features of these tools is their ability to ensure precise part alignment. According to a study by the National Institute of Standards and Technology (NIST), manufacturers using advanced fixtures experience a reduction in setup times by as much as 30%, which leads to increased overall throughput.

Another notable aspect of fixture tools is their versatility. By enabling quick adjustments and easy interchangeability, these tools allow manufacturers to adapt swiftly to varying production requirements. A recent report from Grand View Research highlights that the global fixture tooling market is expected to grow significantly, partly driven by the increasing demand for customized manufacturing solutions. This adaptability not only minimizes downtime but also supports lean manufacturing principles, ultimately fostering a more responsive production process.

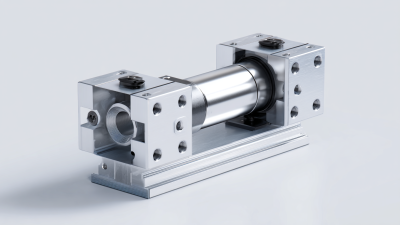

Implementing fixture tools effectively can significantly enhance productivity in modern manufacturing environments. According to a report by the National Institute of Standards and Technology (NIST), manufacturing processes that utilize fixture tools can achieve productivity improvements of up to 25%. This is largely due to the precision and repeatability these tools provide, which minimizes errors and reduces the need for rework. Factories that incorporate well-designed fixture tools not only streamline workflows but also enhance worker safety by reducing manual handling of components.

To maximize output with fixture tools, it is essential to focus on best practices such as proper tool selection, regular maintenance, and employee training. A study conducted by the Society of Manufacturing Engineers (SME) indicated that companies that invest in comprehensive training programs see a 15% reduction in cycle times. By ensuring workers are trained to use fixture tools efficiently, manufacturers can optimize operations further, capitalize on the efficiency gains, and maintain a competitive edge in the industry. Moreover, implementing modular fixture systems can adapt to various tasks, providing flexibility and reducing setup times, as highlighted in the latest Manufacturing Trends Report, making them indispensable in today's fast-paced market.

| Dimension | Before Implementation | After Implementation | % Improvement |

|---|---|---|---|

| Production Speed (units/hour) | 100 | 125 | 25% |

| Error Rate (%) | 5 | 3 | 40% |

| Setup Time (hours) | 4 | 2.5 | 37.5% |

| Labor Cost (per unit) | $20 | $15 | 25% |

| Overall Equipment Effectiveness (%) | 70 | 85 | 21.4% |

The impact of fixture tools on manufacturing performance is becoming increasingly significant in the modern manufacturing landscape. With advancements in technology, especially in the realm of smart manufacturing, these tools are crucial for enhancing efficiency and driving productivity. By providing precise alignment and stability during the manufacturing process, fixture tools reduce setup times and improve the consistency of the output, leading to a remarkable boost in productivity—evidenced by the reported 25% increase.

Moreover, the integration of additive manufacturing techniques like 3D printing into fixture design is revolutionizing how companies approach production challenges. This evolution allows for rapid prototyping and the creation of more complex fixtures that meet specific manufacturing needs. As industries focus on sustainable practices, efficient fixture tools become a vital ingredient in minimizing waste and ensuring quality control. The relationship between equipment reliability and product quality further emphasizes the importance of fixture tools in maintaining performance across multi-stage manufacturing systems.

This chart illustrates the significant boost in productivity observed in modern manufacturing environments after the implementation of fixture tools. Before the adoption of these tools, productivity was at 60%, while it increased to 85% after their integration, showcasing a remarkable 25% improvement.

The future of fixture tool technology is poised to make significant strides in enhancing efficiency within modern manufacturing processes. As industries increasingly integrate automation and smart technologies, fixture tools are evolving to meet the demands for precision and speed. Innovations such as advanced materials and modular designs enable manufacturers to customize fixtures quickly, thereby reducing setup times and enhancing workflow continuity. The synergy of fixture tools with technologies like 3D printing and digital dynamic capabilities allows for more agile production environments, fostering higher productivity levels and reduced waste.

Moreover, sustainability trends are becoming integral to fixture tool advancements. Manufacturers are focusing on creating eco-friendly tools that not only minimize environmental impact but also contribute to operational efficiency. This emphasis on sustainability is resonating across sectors, as businesses recognize the value of investing in technologies that promote resource conservation and energy efficiency. The implications of these trends extend beyond mere productivity gains; they pave the way for a more resilient manufacturing landscape capable of adapting to future challenges.