In the world of manufacturing, achieving optimal efficiency and accuracy is paramount, and Precision Die Cast stands out as a technology that fulfills these criteria remarkably. This technique allows for the production of intricate and highly detailed components with exceptional repeatability, making it a preferred choice across various industries, from automotive to electronics. However, understanding the nuances of Precision Die Cast—such as its design specifications, material selection, and operating conditions—can be daunting for newcomers and even seasoned professionals. In this blog, we aim to demystify the process by providing insightful technical specifications and practical usage tips. Whether you are looking to enhance your existing processes or exploring new applications, our comprehensive examination will unlock the secrets to mastering Precision Die Cast for improved productivity and product quality. Join us as we delve into the examples and best practices that can elevate your die casting endeavors.

China’s precision die casting industry has rapidly evolved into a global powerhouse, renowned for its advanced manufacturing techniques and cost-effective solutions. This growth can be attributed to a combination of factors, including state-of-the-art technology, abundant skilled labor, and favorable government policies that promote industrial expansion. With the rise of industries such as automotive, electronics, and aerospace, China has positioned itself as a critical player in the precision die casting market, meeting the demands for high-quality and precision-engineered components.

In recent years, China's reach has extended far beyond its borders, as manufacturers have established partnerships with international companies. This cross-border collaboration has facilitated the sharing of technology and expertise, enabling Chinese firms to optimize their production processes and enhance product quality.

Furthermore, by participating in global supply chains, China has showcased its capabilities in providing reliable, high-quality die-cast products, solidifying its status as a go-to source for precision components in various markets worldwide. As industries continue to demand seamless integration of precision components, China's die casting sector is poised to maintain its competitive edge on the international stage.

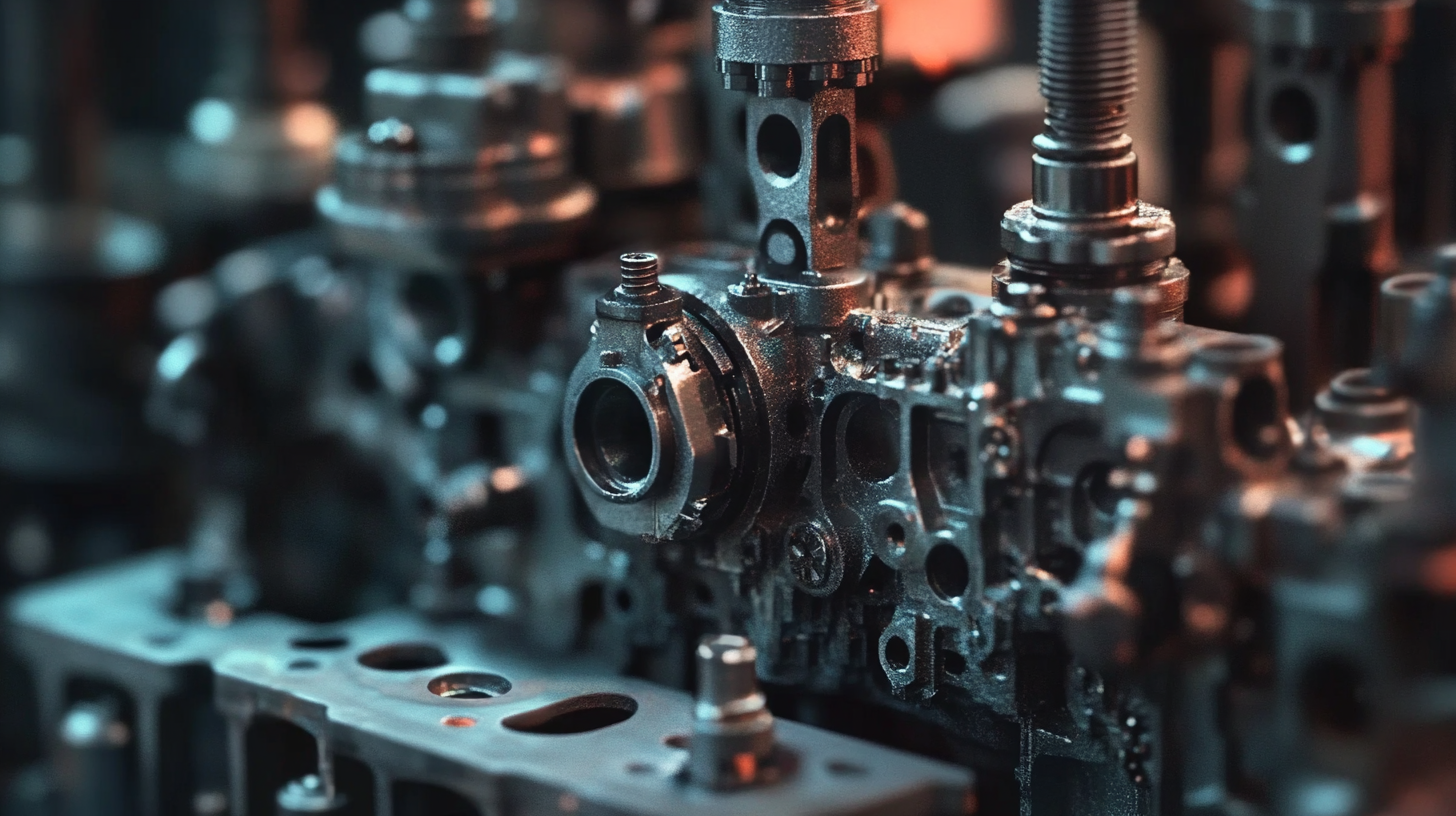

In the realm of precision die casting, understanding the key technical specifications is essential for achieving optimal performance.

Factors such as alloy selection, mold design, and cycle times significantly influence the final quality of casted products.

According to a recent industry report by the Die Casting Association, the right choice of materials can enhance mechanical properties, with aluminum alloys providing excellent strength-to-weight ratios, while zinc alloys offer superior fluidity and fine detail retention.

These specifications guide manufacturers in selecting the ideal materials for their applications, ensuring durability and functionality.

Mold design is another critical element that affects precision in die casting. The cooling system within the mold plays a pivotal role in maintaining uniform temperature control, which is crucial for reducing thermal stress and ensuring even material flow.

Research published by the American Foundry Society indicates that optimizing cooling channels can reduce cycle times by up to 30%, leading to increased productivity and lower manufacturing costs.

Additionally, meticulous attention to surface finish specifications can lead to reduced post-processing requirements and enhanced visual quality of the final product, further contributing to operational efficiency and competitive advantage in the die casting market.

When selecting materials for precision die casting, understanding the properties of different alloys can significantly enhance product quality. Among the most favored materials is the AM60 magnesium alloy, known for its lightweight yet robust characteristics, making it ideal for applications in automotive and aerospace industries. AM60's excellent fluidity during casting facilitates the production of intricate shapes with reduced scrap rates, ultimately improving overall efficiency.

Tips for material selection include assessing the specific requirements of your project, such as strength, ductility, and thermal properties. Conducting thorough research on the alloy composition is crucial; for instance, Al-Si alloys offer exceptional resistance to hot cracking, making them suitable for high-performance applications. Moreover, always consider the cost vs. benefit ratio when choosing alloys, as premium materials can pay off in durability and functionality.

In addition, ensure the compatibility of your selected material with the die casting process. For instance, the gating design and cooling channels must be optimized based on the chosen alloy's thermal conductivity and solidification rates. Investing time in proper material selection and process optimization can lead to enhanced die cast quality and reduced manufacturing challenges.

In the competitive world of precision die casting, adopting best practices is essential for maximizing efficiency and maintaining high-quality output. One effective tip is to thoroughly optimize the die design before starting production. A well-designed die can significantly reduce cycle times, minimize scrap rates, and improve overall product consistency. Engaging in simulations during the design phase can help identify potential issues, allowing for adjustments that can streamline the casting process.

Another crucial aspect is proper temperature control throughout the die casting process. Maintaining consistent temperatures can prevent defects like cold shuts or porosity in the final product. It's advisable to regularly calibrate heating elements and establish a robust monitoring system to track temperature variations. Additionally, utilizing advanced thermal analysis tools can provide valuable insights into heat distribution, further optimizing the die cooling process.

Lastly, implementing a comprehensive maintenance schedule for die casting equipment can lead to enhanced durability and efficiency. Regular inspection and timely repairs not only prolong the lifespan of the machinery but also ensure that production remains smooth and uninterrupted. Creating a detailed maintenance log helps identify patterns and potential issues before they escalate, contributing to a more efficient operational workflow in precision die casting.

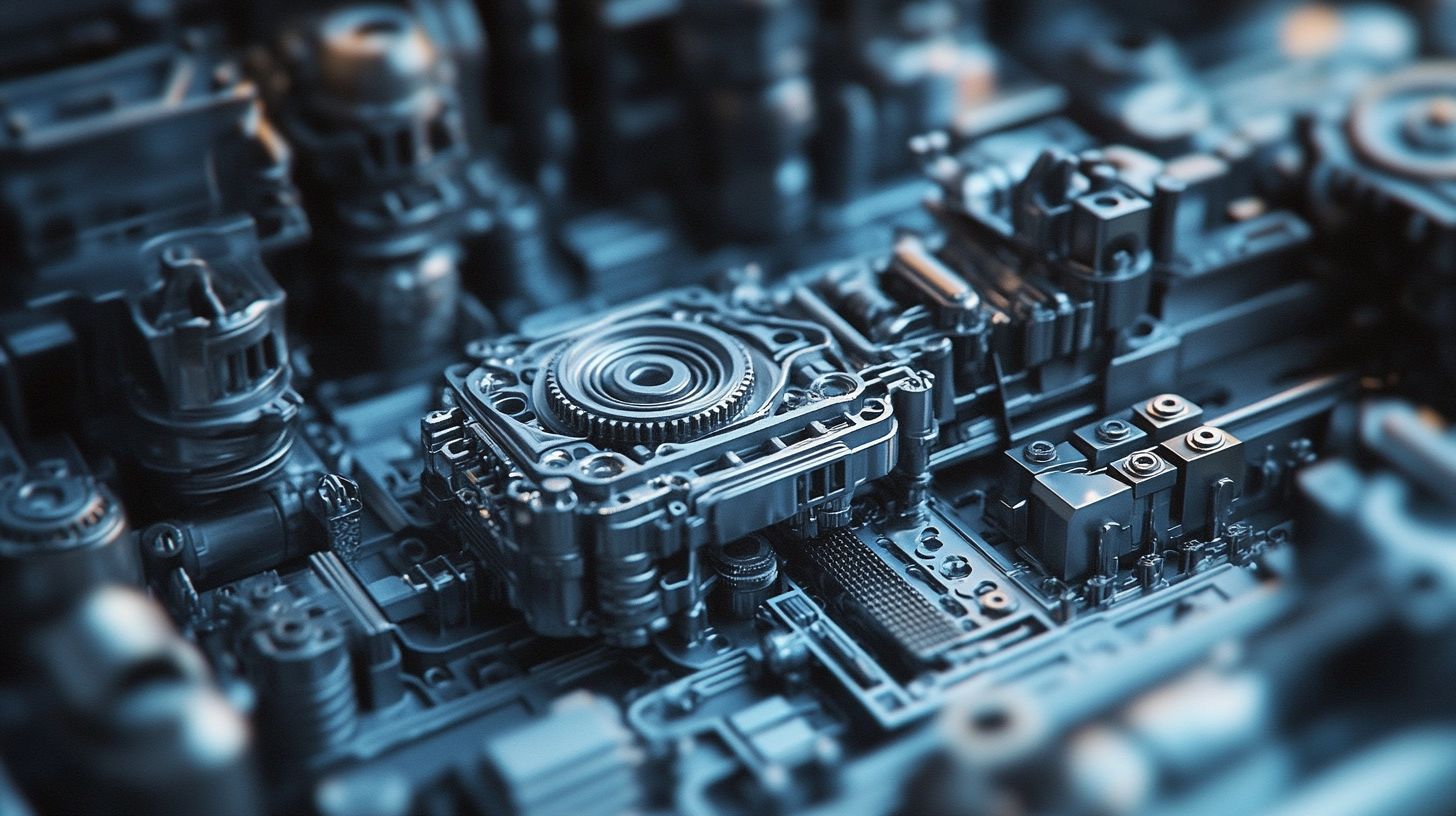

The future of die casting technology is poised for significant transformation as global markets evolve. With the increasing demand for lightweight and durable materials, industries such as automotive, aerospace, and electronics are driving innovations in precision die casting. Advanced manufacturing techniques, including the integration of artificial intelligence and automation, are enabling manufacturers to enhance efficiency and reduce waste. This shift not only streamlines the production process but also improves the quality and precision of casted parts, making them more competitive in the global marketplace.

Moreover, sustainability is becoming a pivotal focus in the die casting sector. As environmental regulations tighten, companies are exploring eco-friendly materials and energy-efficient production methods. The adoption of recycled metals and the emphasis on closed-loop systems are trends gaining momentum, helping to minimize the environmental footprint of die casting processes. As technology continues to advance, we can expect to see a surge in smart die casting solutions that leverage data analytics to optimize operations and predict maintenance needs, ultimately leading to more resilient and adaptable manufacturing environments.