In recent years, the manufacturing industry has witnessed transformative advances in processes that enhance product quality and efficiency, among which Precision Die Cast stands out as a game-changer. According to a report by the Precision Metalforming Association, the global die casting market is expected to reach approximately $15 billion by 2025, driven by increasing demand for lightweight and cost-effective products in sectors such as automotive and aerospace. This technique not only ensures a remarkable level of detail and dimensional accuracy but also significantly reduces waste and production time. As manufacturers continue to integrate precision engineering techniques into their operations, understanding the intricate technical parameters of Precision Die Cast becomes essential for optimizing performance and meeting the evolving demands of the marketplace. This article aims to explore these parameters while providing practical tutorials to facilitate the effective adoption of this revolutionary manufacturing method.

The evolution of die casting techniques has significantly transformed modern manufacturing, pushing the boundaries of what is achievable in precision engineering. Traditionally, die casting was limited to non-ferrous metals, but advancements in technology have broadened the materials used, allowing manufacturers to now incorporate magnesium, zinc, and even aluminum alloys with unparalleled precision. According to a recent market report by Mordor Intelligence, the global die casting market is expected to grow at a CAGR of 5.3% from 2021 to 2026, driven by the increasing demand for lightweight materials in industries such as automotive and aerospace.

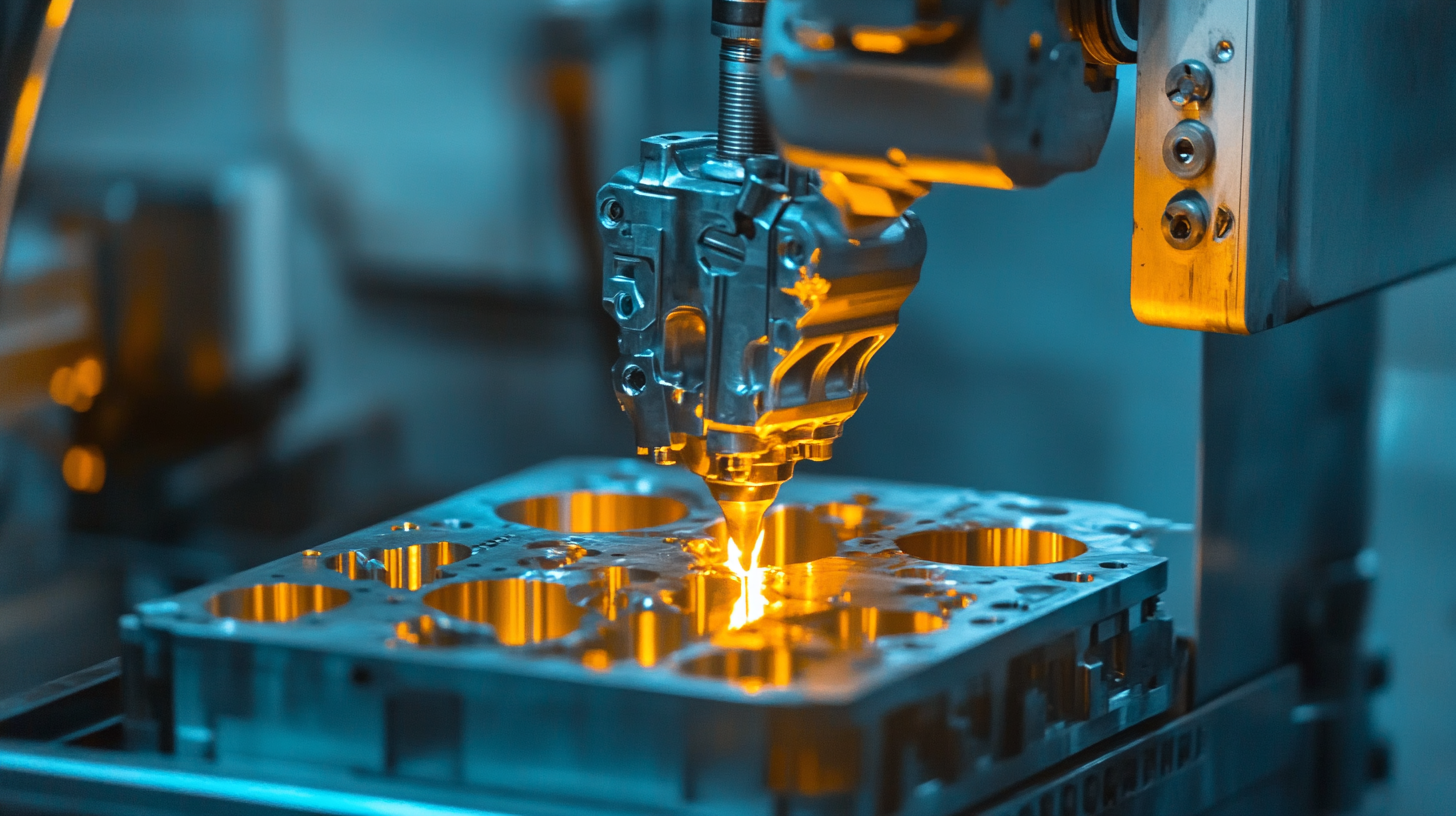

In addition to materials innovation, automation and computer-aided design (CAD) have played crucial roles in refining die casting processes. These technologies enable manufacturers to produce complex geometric shapes with high accuracy and reduced lead times. A study by Grand View Research highlights that automated die casting processes can reduce scrap rates by as much as 15%, representing significant cost savings. Furthermore, the integration of Industry 4.0 principles allows for real-time monitoring and adjustments during manufacturing, ensuring consistent quality and performance that meet the stringent requirements of today’s markets. The rise of these advanced die casting techniques illustrates a remarkable shift towards more efficient, precise, and sustainable manufacturing practices.

Precision die casting has emerged as a game-changer in the manufacturing landscape, particularly for global supply chains. According to a recent report by the Research and Markets, the precision die casting market is expected to grow at a CAGR of 5.2% between 2021 and 2026, reflecting its increasing importance and application across various industries. This technique not only enhances the accuracy and consistency of produced components but also significantly reduces waste, thereby optimizing production efficiency.

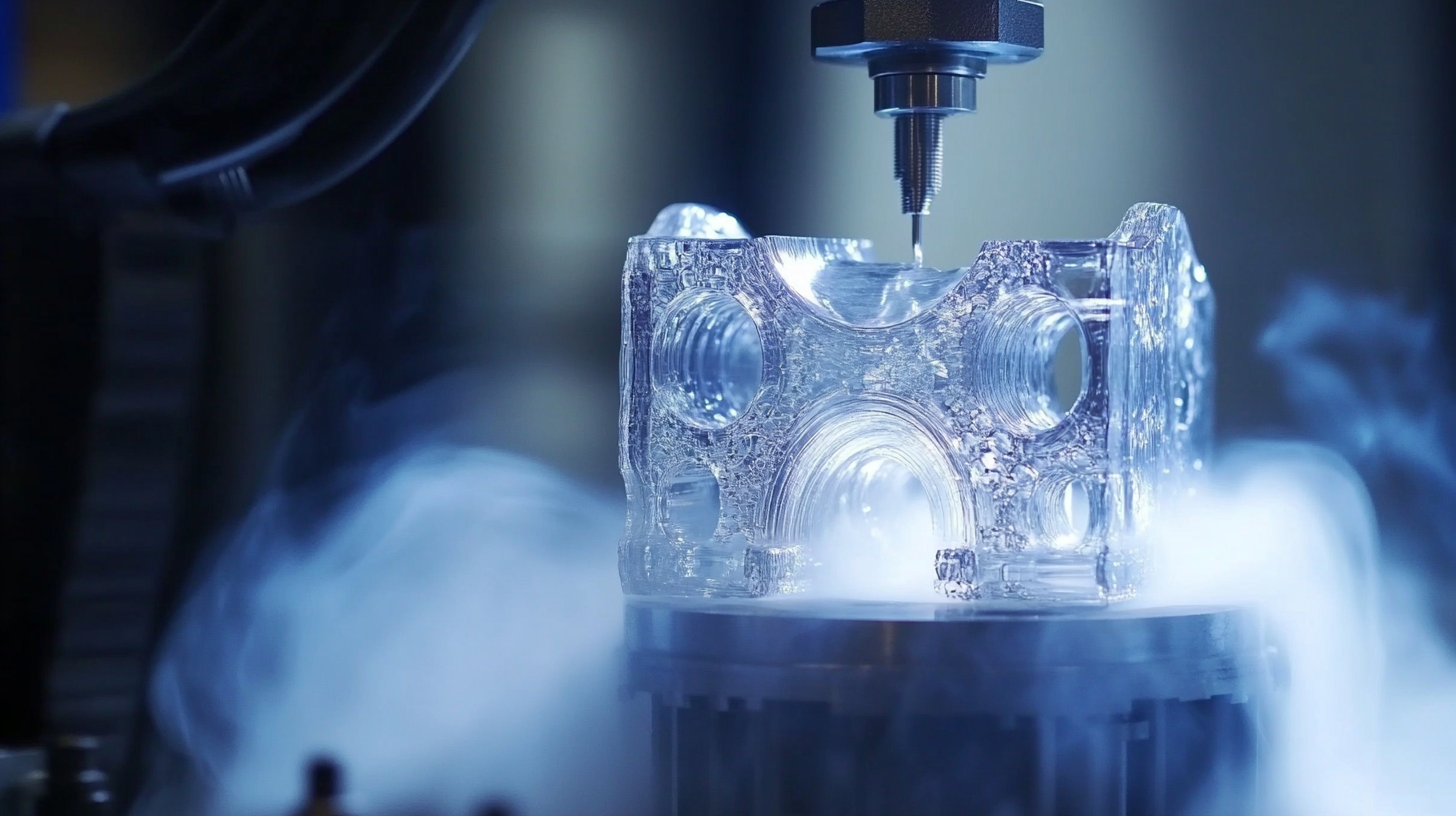

One of the key advantages of precision die casting is its ability to produce complex shapes with tight tolerances, which is crucial for industries such as automotive and aerospace. A study by the American Foundry Society highlights that components manufactured through precision die casting can achieve tolerances as tight as ±0.1 mm, allowing for intricate designs that meet the stringent demands of modern technology. Furthermore, by utilizing materials like aluminum and zinc alloys, precision die casting ensures lightweight yet durable parts, which is essential for enhancing fuel efficiency and performance in transportation sectors. As companies increasingly focus on sustainability and efficiency, precision die casting stands out as a vital technique in modern manufacturing.

China has emerged as a formidable leader in the realm of precision engineering and manufacturing, playing a pivotal role in the evolution of the industry. With a robust infrastructure, skilled workforce, and rapid technological advancements, Chinese manufacturers are at the forefront of producing high-quality precision die cast products. This transformation is largely attributed to a strong focus on research and development, enabling companies to continually innovate and refine their production techniques. As a result, China is not only meeting domestic demands but also catering to international markets with bespoke solutions tailored to various industry needs.

Moreover, China's strategic investments in automation and smart manufacturing technologies have significantly enhanced efficiency and precision in production processes. The integration of cutting-edge techniques such as computer-aided design (CAD) and computer numerical control (CNC) machining has revolutionized traditional manufacturing workflows, ensuring that even the most complex designs can be executed with unparalleled accuracy. As the demand for precision components grows across diverse sectors—from automotive to aerospace—China's industry is well-positioned to provide reliable, precise, and cost-effective solutions that meet the high standards expected in today's global marketplace.

| Category | Aspect | Statistics | Remark |

|---|---|---|---|

| Market Size | Precision Die Casting Industry | $10 Billion | 2023 Estimate |

| Growth Rate | CAGR (2023-2028) | 8.5% | Projected Growth |

| Major Applications | Automotive Components | 65% | Share in Industry |

| Technology Used | Die Casting Techniques | High Pressure, Low Pressure | Common Techniques |

| Leading Producers | Countries | China, Germany, USA | Key Players |

| Sustainability | Recycling Rate | 90% | Material Reuse |

| Innovation | Emerging Technologies | 3D Printing Integration | In Development |

China is emerging as a powerhouse in die casting, leveraging innovative technologies to enhance precision engineering techniques. With over 69% of global rare earth production under its control, China's dominance in the supply of essential materials is pivotal for the die casting industry. The utilization of rare earth elements in advanced manufacturing not only improves the quality of cast products but also drives operational efficiency. As domestic companies continue to innovate, we can expect significant advancements in the precision die casting sector, aligning with the broader trends in high-tech manufacturing.

One key area to watch is the integration of AI technology into precision engineering processes. China's recent embrace of open-source AI has positioned it ahead in rapid technological diffusion, reinforcing the potential for smart manufacturing solutions in die casting. This synergy between AI and advanced manufacturing methodologies is set to transform production lines, facilitate real-time quality control, and reduce lead times in product development.

**Tips:**

1. Embrace digital tools that optimize design and production processes to enhance precision.

2. Stay informed about the latest innovations in material science and AI, as these will be critical in shaping the future of die casting techniques.

3. Foster collaborations within the supply chain to diversify sources of rare materials, ensuring a resilient manufacturing environment.

Sustainability has become a crucial focus in the die casting industry, driving manufacturers to adopt practices that minimize environmental impact. Traditional die casting methods often involve high energy consumption and significant waste generation. However, recent advancements in precision engineering techniques are helping to mitigate these issues. The integration of energy-efficient machines and processes allows manufacturers to reduce their carbon footprint while producing high-quality components. By harnessing innovative technologies and optimizing workflows, companies can achieve sustainable production without compromising precision.

Sustainability has become a crucial focus in the die casting industry, driving manufacturers to adopt practices that minimize environmental impact. Traditional die casting methods often involve high energy consumption and significant waste generation. However, recent advancements in precision engineering techniques are helping to mitigate these issues. The integration of energy-efficient machines and processes allows manufacturers to reduce their carbon footprint while producing high-quality components. By harnessing innovative technologies and optimizing workflows, companies can achieve sustainable production without compromising precision.

Furthermore, the use of recyclable materials is gaining traction in the die casting sector. With the increasing demand for eco-friendly solutions, manufacturers are exploring how to utilize recycled alloys and materials in their casting processes. Not only does this practice contribute to reduced resource extraction, but it also minimizes industrial waste. Companies that prioritize sustainability in their operations are not only meeting regulatory requirements but also appealing to environmentally conscious consumers. By embedding sustainability into the core of their production strategies, die casting manufacturers pave the way for a greener future in manufacturing.