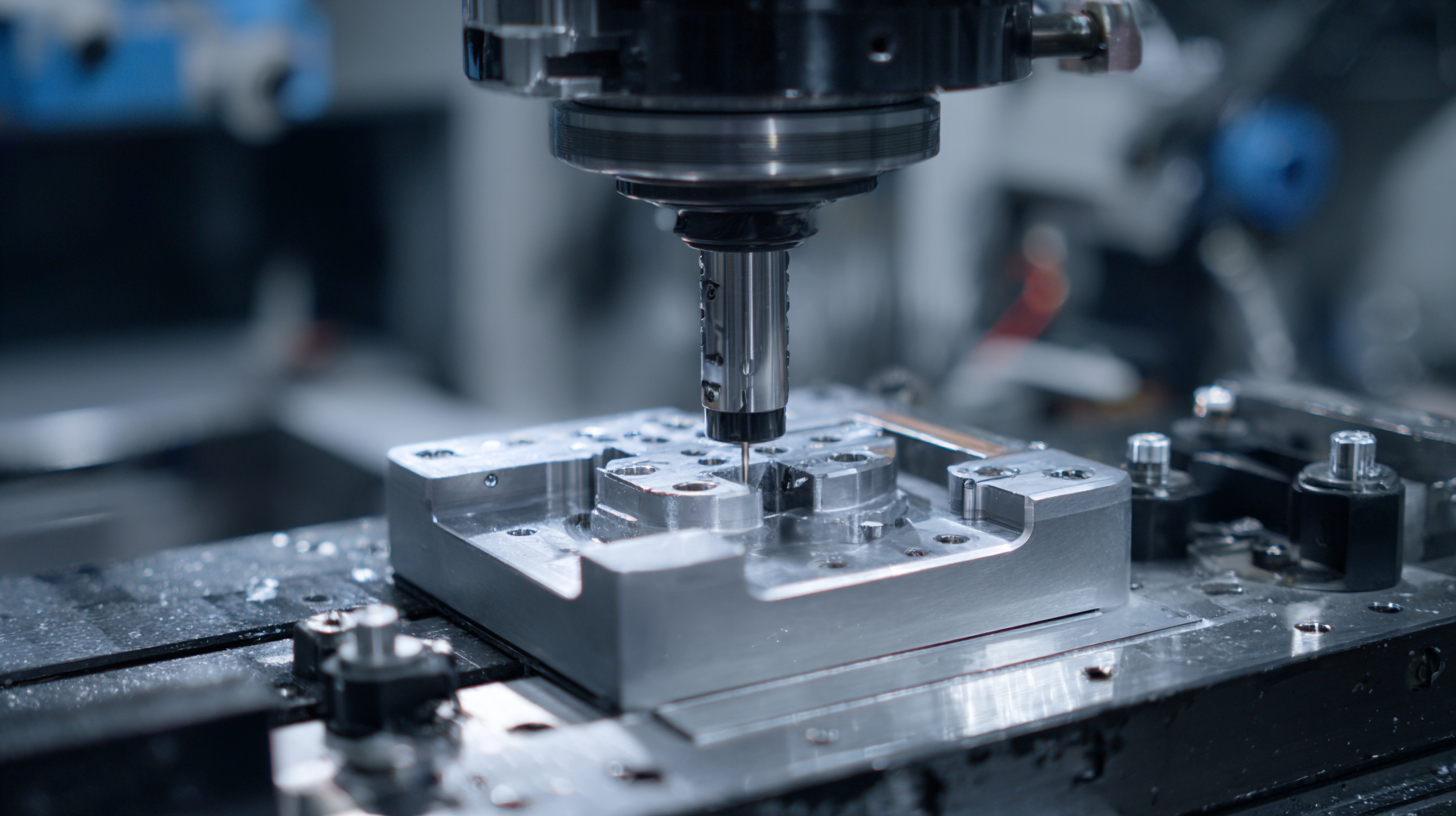

In the rapidly evolving landscape of manufacturing, the importance of CNC fixtures has never been more pronounced. According to a recent report by Mordor Intelligence, the global CNC machining market is expected to reach $100 billion by 2025, underscoring the critical role of efficient production techniques. CNC fixtures serve as essential components that enhance precision, reduce setup times, and ultimately boost overall production efficiency. With manufacturers continuously seeking ways to optimize their processes, innovations in CNC fixture design and technology are pivotal. In this blog, we will explore the seven best CNC fixture innovations that not only streamline workflows but also elevate production efficiency to new heights, ensuring competitive advantage in an increasingly automated industry.

CNC fixture design is evolving rapidly, incorporating new technologies that significantly enhance productivity on the shop floor. One of the most prominent trends is the adoption of modular fixtures, which allow manufacturers to customize setups quickly and efficiently. This flexibility not only reduces downtime between jobs but also enables faster switch-overs, catering to a diverse range of production needs.

To make the most of modular fixtures, consider investing in a comprehensive inventory of interchangeable components. This approach ensures that you can quickly adapt to new projects without the need for extensive reconfiguration, maximizing both time and resource efficiency. Additionally, integrating automation into your fixture systems can optimize workflows, as automated loading and unloading reduce manual handling time and improve accuracy.

Another key innovation in CNC fixture design is the use of advanced materials such as lightweight composites and high-strength alloys. These materials offer durability while minimizing weight, making fixtures easier to handle and reposition. When selecting materials, prioritize options that not only enhance performance but also resist wear and tear over time. By staying updated on these design trends and innovations, manufacturers can significantly elevate their production efficiency and remain competitive in a rapidly changing market.

| Innovation | Description | Benefits | Applications |

|---|---|---|---|

| Modular Fixture Systems | Interchangeable components allow quick reconfiguration. | Reduced setup time and increased flexibility. | Aerospace, automotive manufacturing. |

| Integrated Sensors | Fixtures embedded with sensors to monitor process conditions. | Real-time data for enhanced quality control. | Medical devices, precision machining. |

| Magnetic Clamping Systems | Utilizes magnetic forces for secure hold of components. | Faster loading/unloading, versatile workholding. | Sheet metal processing, custom part fabrication. |

| 3D Printed Fixtures | Custom fixtures manufactured using additive techniques. | Cost-effective production of low-volume runs. | Prototype development, small batch production. |

| Automated Fixture Adjustments | Fixtures that automatically adjust to varying part sizes. | Increases production versatility and reduces downtime. | High-volume manufacturers, automotive assembly lines. |

| Virtual Reality Fixtures | Allows operators to visualize and interact with fixtures in a digital space. | Improved training and design validation processes. | Education, design review. |

| Smart Workholding Solutions | Fixtures equipped with IoT technology for analysis. | Enhanced data collection for predictive maintenance. | Manufacturing analytics, process improvement. |

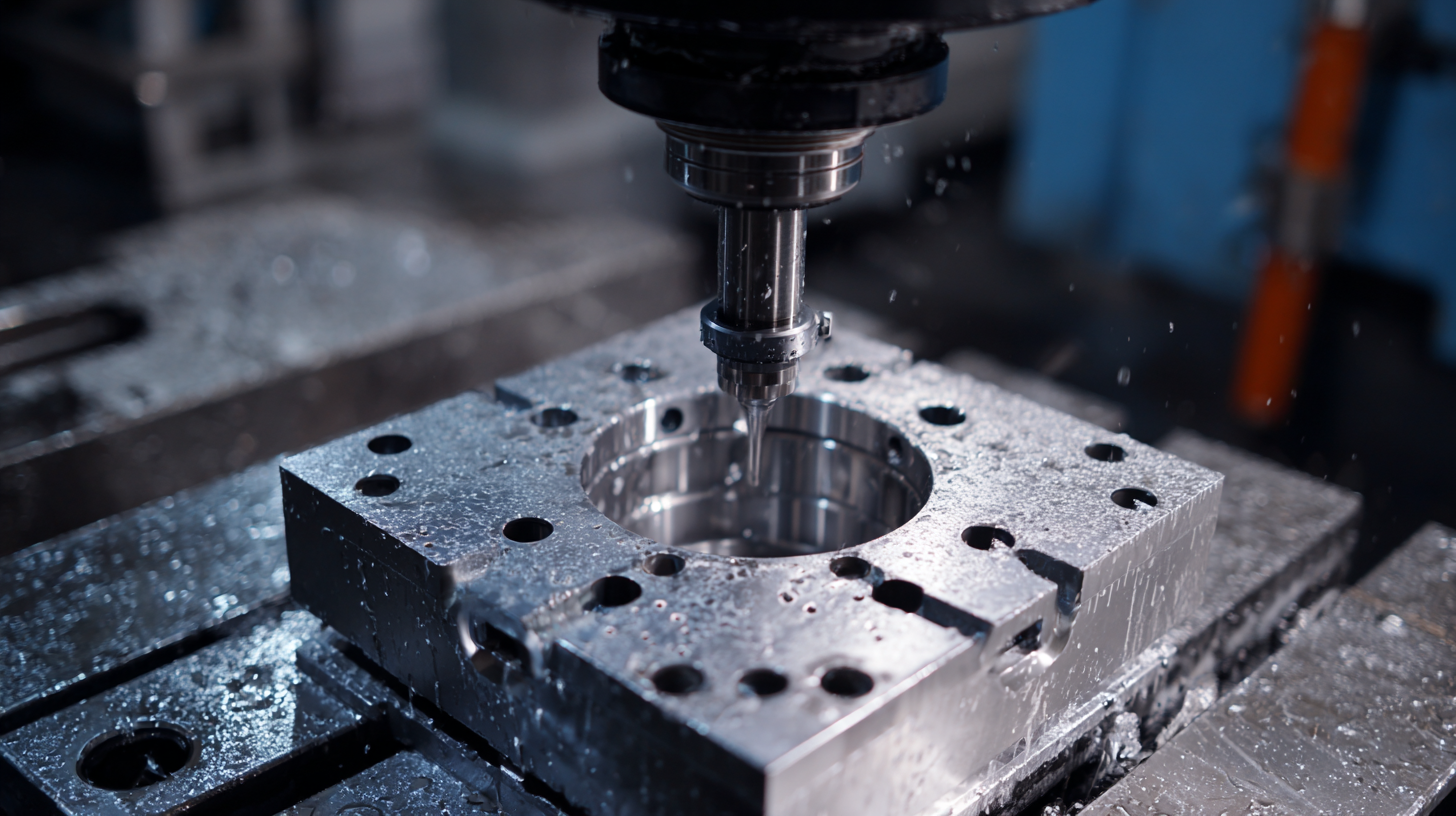

In the realm of CNC fixture manufacturing, innovative materials are playing a pivotal role in enhancing production efficiency. The advent of advanced polymer 3D printing is particularly noteworthy, as it significantly reduces lead times and manufacturing costs associated with traditional tooling fixtures. This technology enables manufacturers to create custom fixturing solutions quickly and with precision, which is critical in competitive industries seeking to optimize their workflows.

Furthermore, the integration of both additive and subtractive manufacturing techniques is transforming the landscape of production. By leveraging these methodologies, companies can streamline their processes, ultimately improving performance and decreasing time-to-market. For instance, the use of production-grade resins in 3D printing not only contributes to the durability of components but also facilitates intricate designs that were previously challenging to achieve. As these innovations continue to evolve, they are set to redefine the standards of efficiency in CNC fixture manufacturing, paving the way for more agile and cost-effective production strategies.

In the ever-evolving world of CNC machining, the integration of automation techniques with CNC fixtures has become vital for enhancing production efficiency. One key innovation is the modular fixture design, which allows manufacturers to tailor setups quickly according to different operational needs. By utilizing a four-sided tooling block, these modular systems can adapt to various configurations, minimizing downtime and maximizing utilization. This flexibility not only streamlines the workflow but also ensures precision in machining processes, ultimately leading to diminished error rates.

Another significant advancement is the implementation of automatic tool changers, which streamline operations by reducing manual intervention. This automation enables CNC machines to switch between tools swiftly, allowing for continuous production cycles and enhanced throughput. Such innovations facilitate a more seamless integration of fixtures with CNC systems, empowering operators to focus on more complex tasks while leaving repetitive actions to automated systems. By leveraging these technologies, manufacturers can achieve higher productivity levels and maintain competitiveness in a fast-paced market.

In the realm of CNC machining, the implementation of advanced fixtures has been a game-changer for many manufacturers. The integration of innovative CNC fixtures can significantly enhance production efficiency, as evidenced by various case studies. For instance, a leading automotive parts manufacturer adopted a modular fixture system that allowed for rapid changeovers between different part types. This flexibility not only reduced downtime but also increased the overall throughput, leading to a 30% boost in production rates.

Another compelling example comes from a precision aerospace component supplier. By investing in intelligent fixtures equipped with sensors and real-time data analytics, the company was able to monitor the machining process closely. This system enabled proactive adjustments during production, minimizing waste and ensuring higher accuracy. As a result, they reported a dramatic reduction in scrap rates and an increase in customer satisfaction due to consistent, high-quality output. Such success stories highlight the transformative impact of embracing advanced CNC fixture technologies in modern manufacturing environments.

Customizing CNC fixtures to meet specific production needs is crucial for enhancing efficiency and productivity in manufacturing. According to a report by IBISWorld, the CNC machining industry has experienced a steady growth rate of about 4.5% annually, driven by advancements in automation and the rising demand for precision engineering. A tailored CNC fixture not only aids in maximizing production speed but also minimizes human error, ultimately leading to improved product quality.

To customize CNC fixtures effectively, manufacturers should start by conducting a thorough analysis of their production requirements. Data from the National Institute of Standards and Technology highlights that adopting a custom fixture design can reduce setup times by up to 30%. By utilizing CAD software, manufacturers can simulate various designs, ensuring that the fixture optimally accommodates the specific parts being machined. Incorporating features such as modular components can further enhance flexibility, allowing manufacturers to adapt their processes quickly in response to changing demands. This innovative approach not only streamlines production but also aligns with the industry's push towards lean manufacturing practices, fostering a more sustainable production environment.