In the ever-evolving landscape of the manufacturing industry, the materials used play a pivotal role in determining the efficiency, durability, and overall success of production processes. Among the various materials available, Aluminium Parts have emerged as a preferred choice for many manufacturers. The unique properties of aluminium, such as its lightweight nature, corrosion resistance, and excellent machinability, make it an ideal candidate for a wide range of applications across various sectors. As industries strive to enhance performance and reduce costs, understanding the benefits of incorporating Aluminium Parts into manufacturing processes becomes essential.

The versatility of Aluminium Parts facilitates innovation, enabling manufacturers to design more efficient products while maintaining high standards of quality. By leveraging the advantages of aluminium, companies can enhance their operational efficiency, minimize production time, and ultimately achieve significant cost savings. From automotive to aerospace, the utilization of Aluminium Parts not only improves product performance but also contributes to sustainable manufacturing practices. In this article, we will delve into the top 10 benefits of using Aluminium Parts in the manufacturing industry, elucidating how they can transform production and lead to enhanced outcomes.

Aluminium's lightweight advantage has transformed the manufacturing landscape, providing significant enhancements in efficiency and productivity. According to a report from the International Aluminium Institute, aluminium is 35% lighter than steel, making it an ideal choice for components that demand durability without the added weight. This reduction in weight not only facilitates easier handling and transportation of parts but also contributes to energy savings in manufacturing processes. For instance, lighter machinery enables faster operation speeds, ultimately leading to increased output and reduced cycle times.

Moreover, the structural efficiency of aluminium allows for innovative design solutions that further capitalize on its lightweight nature. The global manufacturing sector has seen a shift towards aluminium due to its high strength-to-weight ratio, which can lead to a decrease in material usage without compromising product integrity. According to a study published by the Journal of Materials Processing Technology, using aluminium can improve overall production efficiency by up to 20% compared to traditional materials. As industries strive to meet growing sustainability and performance standards, aluminium provides a crucial advantage that enhances operational efficiency while supporting environmental goals through reduced energy consumption and lower carbon emissions during production.

Aluminium parts are increasingly recognized for their cost-effectiveness in the manufacturing industry, particularly in mass production scenarios. According to a report by the Aluminium Association, the lightweight nature of aluminium—approximately 30% lighter than steel—can significantly reduce shipping costs and energy consumption during production. This reduction in weight contributes to lower operational costs throughout the product lifecycle. Furthermore, aluminium's natural resistance to corrosion means reduced maintenance costs for end products, making it an economically viable choice for manufacturers looking to enhance their margins.

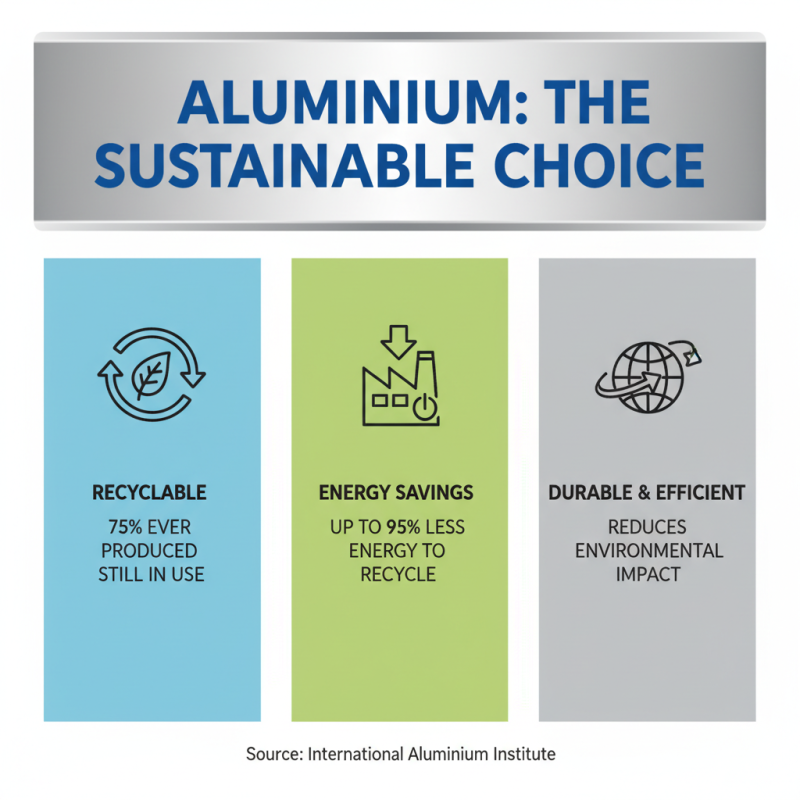

Another significant benefit of aluminium parts is their recyclability, which plays a crucial role in reducing material costs. The Recycling Partnership highlights that recycling aluminium saves up to 95% of the energy required to produce new aluminium from raw materials. This energy efficiency not only helps manufacturers lower their production costs but also aligns with sustainability goals increasingly demanded by consumers and regulations alike. Moreover, as demand for eco-friendly practices grows, businesses utilizing recycled aluminium can position themselves favorably in the market while benefiting from enhanced profitability.

| Benefit | Description | Cost-Effectiveness Rating (1-10) |

|---|---|---|

| Lightweight | Aluminium parts reduce overall product weight, improving transport and handling efficiency. | 9 |

| Corrosion Resistance | Naturally resistant to corrosion, aluminium enhances durability and reduces maintenance costs. | 8 |

| High Strength-to-Weight Ratio | Aluminium offers excellent strength without the weight, beneficial for structural applications. | 9 |

| Recyclability | Aluminium is fully recyclable, promoting sustainability and reducing environmental impact. | 10 |

| Machinability | Easy to machine, aluminium parts have lower production costs and faster turnaround times. | 8 |

| Heat Conductivity | Aluminium has excellent thermal conductivity, making it ideal for heat exchangers and cooling systems. | 7 |

| Aesthetic Appeal | Aluminium can have a sleek and modern look, enhancing the product's marketability. | 7 |

| Electrical Conductivity | Aluminium is an excellent conductor of electricity, favored in electrical applications. | 8 |

| Low Density | Lower density allows for the production of lighter components without compromising strength. | 9 |

| Cost Efficiency | Aluminium parts can be cheaper to produce in larger quantities due to their lightweight nature. | 9 |

Aluminium has emerged as a preferred material in the manufacturing industry, particularly due to its exceptional corrosion resistance. This property extends the lifespan of manufactured goods significantly, making aluminium parts ideal for a variety of applications. According to a study by the Aluminium Association, products made from aluminium can last up to 50 years without significant deterioration in most environmental conditions, compared to steel, which may require replacement after only 15 years in similar settings. This longevity not only benefits manufacturers by reducing replacement costs but also enhances the sustainability profile of the products.

When considering corrosion resistance, it's essential to understand the benefits it brings to various industries. In environments exposed to moisture, chemicals, or saline conditions, aluminium's natural oxide layer acts as a protective barrier. A report from the International Aluminium Institute indicates that the use of aluminium parts can lead to a 20% increase in maintenance intervals for machinery and infrastructure. This reduction in maintenance frequency not only saves costs but also minimizes downtime, leading to increased productivity across operations.

**Tips for Implementation:** When integrating aluminium parts into your manufacturing processes, ensure that the surface finishes are aligned with the specific environmental conditions they will encounter. Finishing treatments, such as anodizing, can further enhance corrosion resistance. Additionally, keep an eye on innovations in aluminium alloys that offer improved performance metrics, which can help in selecting the right material for your manufacturing needs.

This bar chart illustrates the top 10 benefits of using aluminium parts in the manufacturing industry, focusing on aspects like corrosion resistance, weight reduction, and thermal conductivity among others.

Aluminium, known for its lightweight and durable properties, has emerged as a crucial material in the manufacturing industry. One of the most significant advantages of using aluminium parts is their recyclability, making them a sustainable choice for manufacturers seeking to reduce their environmental impact. According to a report by the International Aluminium Institute, nearly 75% of all aluminium ever produced is still in use today, demonstrating the material's longevity and ability to be recycled without loss of quality. This not only conserves resources but also requires significantly less energy—up to 95% less—compared to primary aluminium production.

Moreover, the recycling process of aluminium is highly efficient and environmentally friendly. The Carbon Trust reports that recycled aluminium can reduce carbon emissions by as much as 90% compared to producing new aluminium from ore. With global efforts to combat climate change and promote sustainability, embracing aluminium in manufacturing aligns with the industry's push towards greener practices. By integrating recycled aluminium parts, manufacturers can lower their carbon footprints while still benefiting from the material's strength and versatility, ultimately contributing to a more sustainable future for the industry.

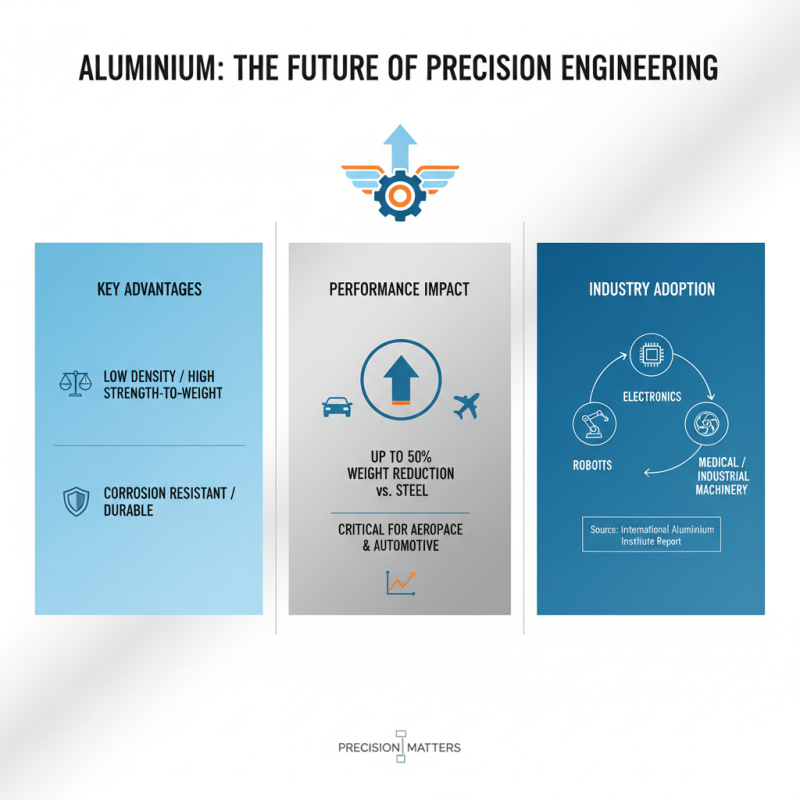

Aluminium has become a critical material in precision engineering, particularly for high-performance applications across various manufacturing sectors. Its low density combined with impressive mechanical properties, such as strength-to-weight ratio, makes it ideal for industries requiring strict adherence to quality and performance standards. For instance, according to a report by the International Aluminium Institute, aluminium parts can reduce overall component weight by up to 50% compared to traditional materials like steel, which is crucial for industries such as aerospace and automotive where every gram counts.

Moreover, aluminium's natural corrosion resistance enhances its longevity and performance stability, especially in challenging environments. This durability is essential in high-performance applications where components are subject to extreme conditions. Data from the Aluminium Association indicates that when used in automotive applications, aluminium can improve fuel efficiency by as much as 10% due to the weight savings. Additionally, the material is easily recyclable, with about 75% of the aluminium ever produced still in use today, further contributing to its appeal in precision engineering by supporting sustainability goals within the manufacturing industry.