In the rapidly evolving landscape of manufacturing, the demand for innovative solutions in assembly processes is more critical than ever. As we look toward 2025, the role of assembly fixtures—essential tools that provide precise alignment and support for components during assembly—will be pivotal in enhancing efficiency and productivity. Industry expert Dr. Emily Foster, a leading authority on automation technologies, has noted, "The future of assembly fixtures lies in their ability to integrate seamlessly with digital frameworks, revolutionizing production lines and minimizing downtime."

Embracing advanced technologies such as AI, IoT, and machine learning, the assembly fixture industry is poised for significant transformation. In this forthcoming landscape, organizations that invest in smart assembly fixture solutions will not only streamline their operations but also adapt swiftly to changing demands. This shift will enable manufacturers to achieve greater flexibility and precision while maintaining consistent quality standards.

As we explore the top assembly fixture solutions for 2025, it becomes increasingly clear that the convergence of digitalization and fixture design will set the stage for unprecedented advancements. By leveraging these insights, companies can embark on a journey toward enhanced efficiency and competitiveness in the assembly domain.

In 2025, the landscape of assembly fixtures is set to be transformed by innovative technologies that promise to boost operational efficiency across various industries. The integration of smart automation, including robotic systems and AI-driven analytics, is revolutionizing the way assembly lines function. These advanced technologies not only enhance precision and reduce human error but also enable real-time monitoring and data collection, allowing for rapid adjustments and improvements in production processes.

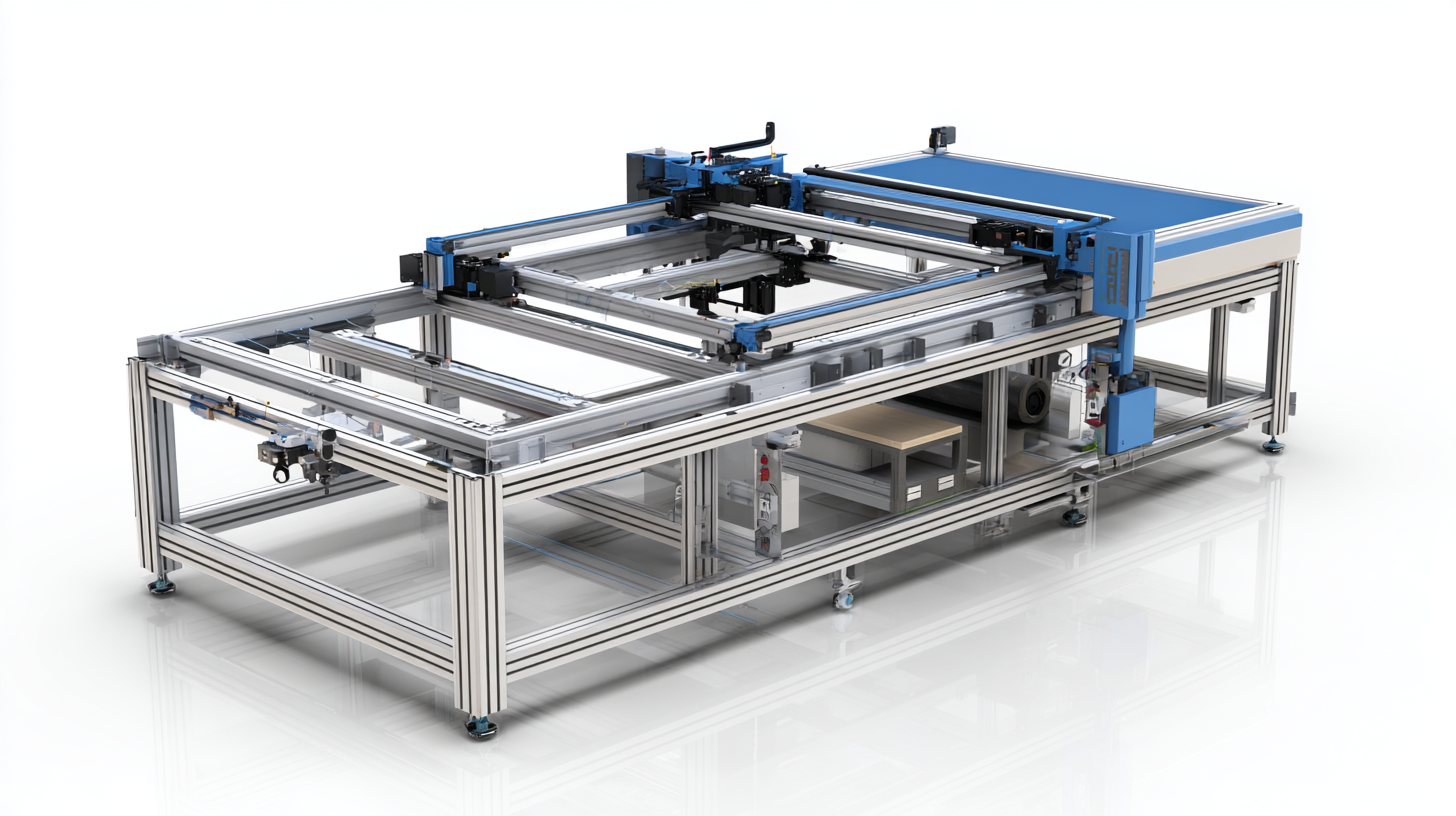

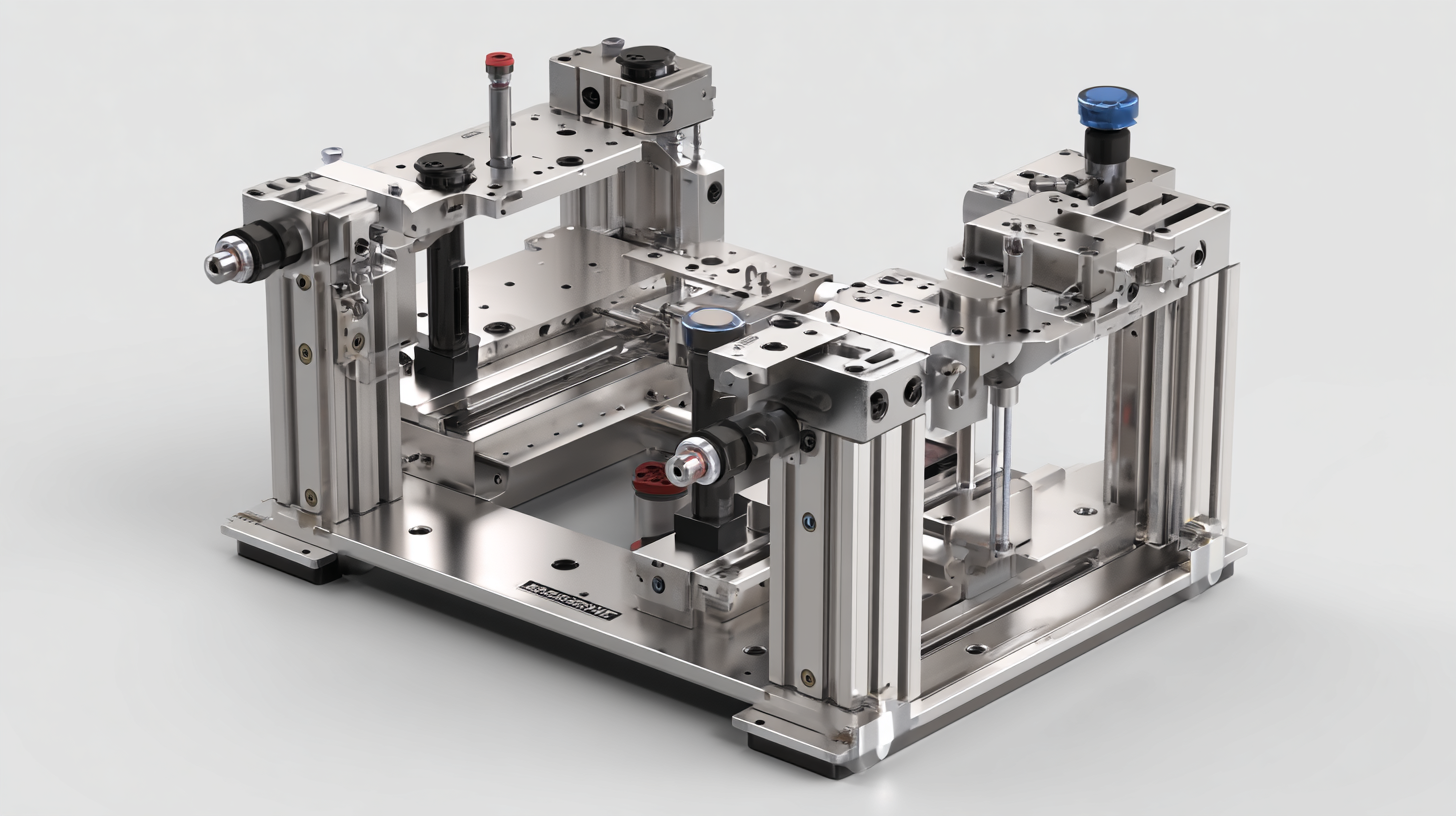

Moreover, the advent of modular and adaptive fixture designs is reshaping traditional assembly methods. These flexible systems can be easily reconfigured for different products, significantly reducing setup times and increasing throughput. Coupled with augmented reality (AR) tools, technicians can receive guided instructions directly in their field of vision, further improving accuracy and speeding up training processes for new staff.

As companies embrace these cutting-edge solutions, the result is a more agile and efficient manufacturing environment, poised to meet the demands of a fast-evolving market in 2025.

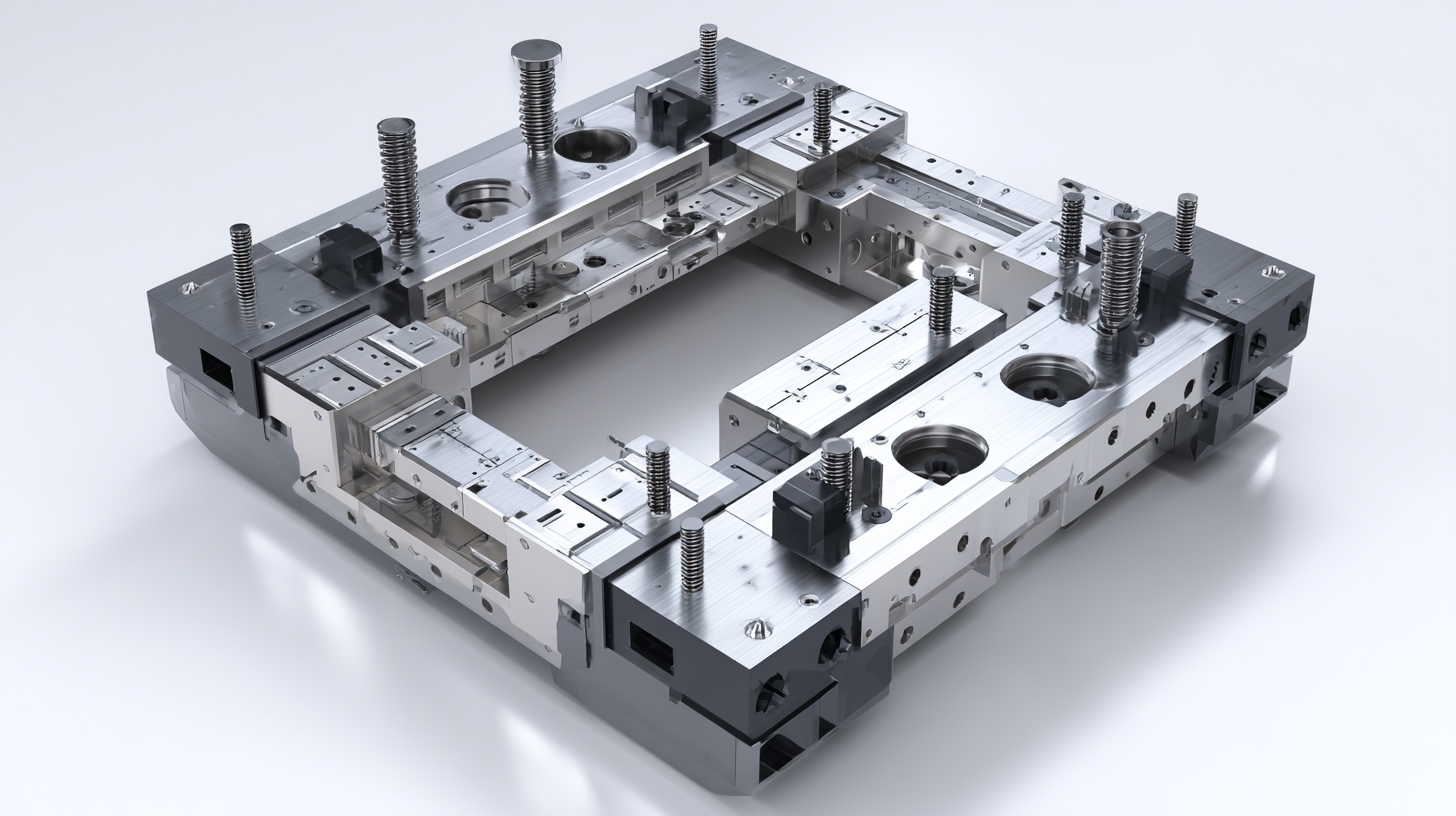

The impact of automation on assembly fixture design is profound, ushering in a new era of efficiency and precision. As manufacturers increasingly adopt automated systems, the demand for fixtures that can seamlessly integrate with robotic processes has skyrocketed. These modern fixtures not only need to accommodate advanced robotic arms but also require versatility to handle a variety of components without extensive reconfiguration. This flexibility allows for quicker changeovers between different assembly tasks, ultimately reducing downtime and increasing output.

Moreover, automation in the assembly process enhances production efficiency by minimizing human error and optimizing workflow. Intelligent fixtures equipped with sensors and connectivity features provide real-time data that can be analyzed for performance improvement. This data-driven approach allows for predictive maintenance, ensuring that machines remain operational and productive. As a result, manufacturers are able to produce higher quality products at a faster pace, meeting the evolving demands of the market while keeping costs under control. The synergy between automation and assembly fixture design is clearly set to redefine manufacturing standards in 2025 and beyond.

Measuring the return on investment (ROI) of advanced assembly fixtures is essential for manufacturers looking to enhance efficiency in 2025. To effectively gauge ROI, metrics such as increased production speed, reduced labor costs, and improved product quality must be analyzed. By implementing advanced fixtures, companies can streamline their assembly processes, leading to faster turnaround times and minimized downtime. These improvements not only boost output but also reduce the overall cost per unit, providing manufacturers with a compelling financial case for upgrading their equipment.

To quantify the benefits of advanced assembly fixtures, manufacturers should utilize key performance indicators (KPIs) such as throughput rates, defect rates, and employee productivity metrics. Analyzing these factors before and after the integration of new assembly technologies will provide clear evidence of profitability. Furthermore, businesses can consider the long-term impact of employee satisfaction and skill development, which often increase when workers utilize enhanced tools, thereby fostering a more engaged workforce. This holistic approach to measuring ROI can guide strategic decisions and drive sustained operational improvements in the manufacturing sector.

In 2025, the assembly fixture industry is poised to embrace sustainability as a pivotal focus, driven by the need to reduce waste and enhance operational processes. Manufacturers are increasingly adopting eco-friendly materials and innovative designs to create fixtures that not only meet production demands but also minimize environmental impact. The integration of recyclable and biodegradable materials is becoming more common, ensuring that assembly fixtures contribute positively to the lifecycle of products by reducing landfill contributions.

Moreover, advanced technologies such as automation and smart manufacturing are being leveraged to streamline assembly processes, further supporting sustainability. By utilizing data analytics and real-time monitoring, companies can identify inefficiencies in their operations and make informed decisions that diminish resource consumption. This shift towards smarter assembly practices not only fosters environmental responsibility but also enhances overall productivity, proving that sustainable practices can align with business efficiency objectives in the fast-evolving landscape of 2025.

In 2025, companies are reimagining their assembly processes through innovative fixture solutions that significantly enhance efficiency. Notable examples include tech giant AXYZ, which has developed a modular assembly fixture that allows for quick adjustments and maintenance. This flexibility not only reduces downtime but also accommodates various production tasks seamlessly. Meanwhile, automotive manufacturer SpeedAuto has implemented an automated fixture system that integrates advanced robotics, drastically improving throughput while reducing human error.

**Tips:** To enhance assembly fixture efficiency, consider investing in modular designs that permit easy upgrades and adjustments. Additionally, employing automation can streamline operations and minimize the manual labor required in assembly lines, ultimately leading to faster production cycles.

Leading the charge in fixture innovation is FastTrack Industries, which employs real-time data analytics to optimize their assembly lines. This approach enables rapid identification of bottlenecks and proactive adjustments, ensuring a smooth workflow. Such data-driven strategies showcase the importance of analytics in maximizing fixture performance.

**Tips:** Utilizing data analytics can provide valuable insights into your assembly operations. Regularly monitor and analyze performance metrics to identify inefficiencies and areas for improvement.

| Company | Fixture Type | Efficiency Improvement (%) | Implementation Year | Key Benefits |

|---|---|---|---|---|

| Company A | Automated Assembly Fixture | 25% | 2025 | Reduced labor costs, Increased speed |

| Company B | Modular Assembly Fixture | 30% | 2025 | Flexibility, Space optimization |

| Company C | Robotic Fixture System | 40% | 2025 | Precision, Consistency |

| Company D | Ergonomic Fixture Design | 20% | 2025 | Improved worker safety, Comfort |

| Company E | Customizable Fixture Solutions | 35% | 2025 | Adaptability, Increased throughput |