In an era where tariffs and trade wars dictate the landscape of global manufacturing, China's aluminum casting industry has shown remarkable resilience and growth. The ability to harness innovations in Prototype Aluminum Casting has played a pivotal role in maintaining competitiveness despite escalating duties imposed by the United States. With China's strategic focus on advanced manufacturing techniques, particularly in aluminum casting, manufacturers are not only navigating the challenges presented by tariff increases but are also leveraging new technologies to enhance production efficiency and product quality. This blog delves into the ways Chinese manufacturers are adopting cutting-edge aluminum casting innovations to thrive in a competitive tariff environment, emphasizing the significance of Prototype Aluminum Casting in this transformative process. Through exploring these advancements, we can gain insights into how the industry is positioned to respond dynamically to contemporary challenges while setting a benchmark for future growth.

The impact of tariffs on the aluminum casting industry is becoming increasingly pronounced as U.S. manufacturers face the challenges of higher costs and potential disruptions in trade. With the imposition of sweeping 25% tariffs on imported steel and aluminum, the industry finds itself navigating a complex landscape. Tariffs intended to protect domestic industries may inadvertently stifle growth and innovation. American aluminum casting manufacturers now grapple with the dual pressures of increased raw material costs and the competitive disadvantage posed by retaliatory measures from international partners.

In response to these challenges, it's essential for aluminum casting companies to leverage innovations and optimize their operations. This could involve investing in advanced technologies that enhance efficiency or exploring alternative supply chains less affected by tariffs. Additionally, a focus on sustainability and environmentally friendly practices could help differentiate these companies in a crowded market, appealing to a growing customer base that prioritizes green production methods. As the industry adapts to the ongoing tariff environment, it must remain agile and proactive to mitigate risks and seize new opportunities for growth.

| Region | Tariff Rate (%) | Market Size (Billion USD) | Growth Rate (%) | Major Innovations |

|---|---|---|---|---|

| North America | 25 | 12.5 | 3.5 | 3D Printing, Hybrid Casting Methods |

| Europe | 10 | 15.3 | 4.2 | Smart Manufacturing, Automation |

| Asia-Pacific | 5 | 20.5 | 6.0 | Aluminum Alloys, Energy Efficient Processes |

| Latin America | 15 | 8.0 | 2.0 | Recycling Technologies, Lightweighting Solutions |

| Middle East | 20 | 5.0 | 3.0 | Advanced Casting Techniques, Digital Twins |

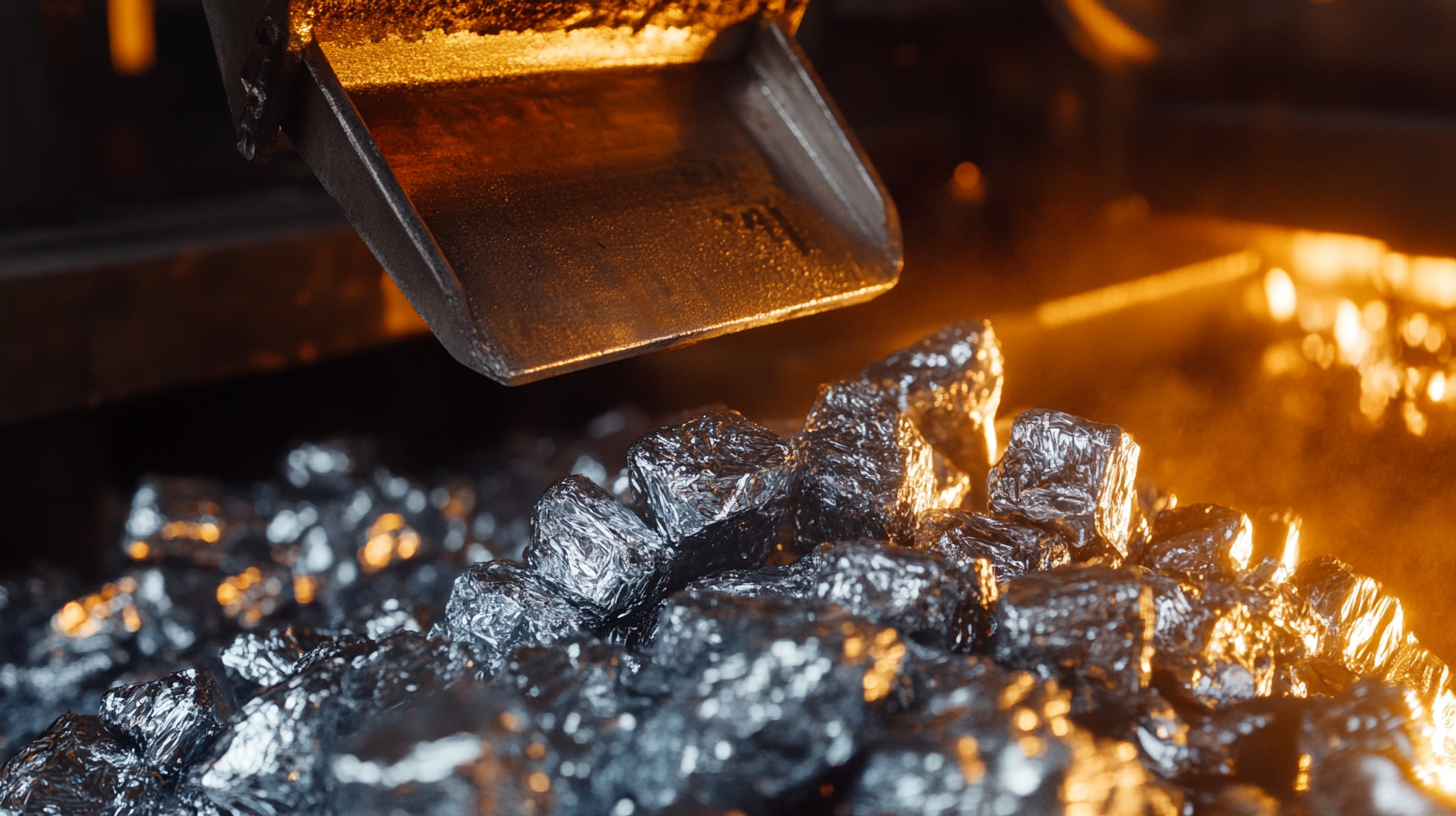

The landscape of aluminum manufacturing in China has undergone a remarkable transformation due to innovative technologies that are reshaping the industry. With the rising demand for lightweight materials across various sectors, manufacturers are increasingly adopting advanced casting techniques and automation. These innovations not only enhance production efficiency but also improve product quality, meeting the stringent requirements of international markets. The integration of smart technologies such as artificial intelligence and Internet of Things (IoT) is enabling real-time monitoring and optimization of casting processes, resulting in lower energy consumption and reduced waste.

In a competitive tariff environment, the ability to leverage technological advancements becomes crucial for sustaining growth. Chinese aluminum manufacturers are focusing on R&D to develop high-performance alloys and more efficient casting methods. This shift is not just a response to external pressures but also a strategy to enhance their competitiveness on a global scale. As they push the boundaries of traditional aluminum casting, these innovations are setting new standards in material properties and applications, positioning Chinese manufacturers to thrive even amidst challenging economic conditions.

In today's tariff-ridden global marketplace, aluminum casting businesses must employ innovative strategies to maintain competitiveness. According to a recent industry report by the Aluminum Association, the U.S. aluminum industry generates approximately $75 billion annually, with tariffs significantly affecting raw material costs and product pricing. Companies must adapt by leveraging technology and improving operational efficiencies. Implementing advanced manufacturing processes such as 3D printing and automation can significantly reduce production costs, providing a buffer against the rising expenses caused by tariffs.

Tip: Invest in employee training programs focused on new technologies to enhance productivity and reduce time-to-market for new products.

Furthermore, exploring alternative supply chains can mitigate the risks associated with tariff increases. Diversifying suppliers and sourcing materials from countries with minimal tariffs can lead to cost savings. A study from McKinsey highlights that companies that strategically diversify their supply chains can improve their profit margins by up to 15%.

Tip: Regularly assess and adjust supplier relationships to ensure you are capitalizing on the most competitive pricing and reliable delivery channels, helping you to navigate the complexities of a fluctuating tariff landscape.

In the current competitive tariff environment, aluminum casting manufacturers must prioritize both quality and efficiency to maintain market relevance. A recent report from the Aluminum Association indicates that the overall demand for aluminum castings is projected to reach 8.5 million metric tons by 2025, driven by the automotive and aerospace sectors, which require high-performance components. This increasing demand makes it imperative for companies to invest in innovative casting technologies to enhance product quality while reducing production costs.

To overcome trade barriers imposed by tariffs, manufacturers are turning to advanced techniques such as automated casting processes and additive manufacturing. According to a study by MarketsandMarkets, the global market for aluminum casting is expected to grow at a CAGR of 5.8% from 2020 to 2025. Companies that adopt cutting-edge solutions can achieve significant improvements in casting precision and lead times, allowing them to offer superior products that meet stringent international standards. By focusing on these areas, businesses can not only navigate the complexities of a tariff-laden environment but also position themselves as leaders in quality and efficiency in the aluminum casting industry.

This bar chart illustrates the impact of aluminum casting innovations on production efficiency and quality ratings over recent years, highlighting how these factors help overcome trade barriers amid a competitive tariff environment.

As the aluminum casting industry navigates a competitive tariff environment, the focus on sustainability and innovation has never been more crucial. Recent studies indicate that the global aluminum casting market is projected to grow from $23.2 billion in 2021 to $34.9 billion by 2026, with a compound annual growth rate (CAGR) of 8.7%. This growth is partly driven by increasing demand for lightweight materials in automotive and aerospace applications, which are now prioritizing environmental footprints alongside performance.

Sustainability initiatives are reshaping production processes within the industry. According to the Aluminum Association, using recycled aluminum can save up to 95% of the energy needed to create new aluminum. The integration of advanced casting technologies, such as 3D printing and automation, is enhancing material efficiency and reducing waste. Moreover, companies are increasingly experimenting with environmentally-friendly alloys and coatings to meet both regulatory standards and consumer preferences for greener products. These innovations not only bolster sustainability but also provide a competitive edge in a market where eco-conscious consumers are becoming a significant driving force.