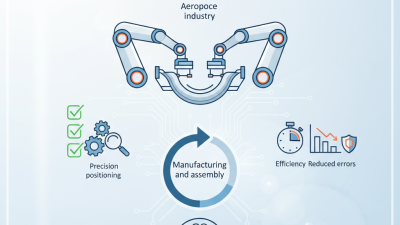

Aerospace fixtures play a crucial role in aircraft manufacturing. These specialized tools hold, support, and align various aircraft components during assembly. Without proper fixtures, the precision required for aircraft safety and performance may be compromised.

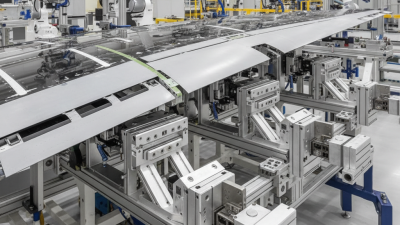

In the complex world of aerospace production, each component must fit perfectly. Fixtures ensure that every part meets strict specifications. For instance, when assembling wings or fuselage sections, the alignment must be exact. Any deviation can lead to catastrophic failures.

However, one must reflect on the challenges these fixtures present. Creating highly accurate fixtures can be time-consuming and costly. Additionally, manufacturers face the task of maintaining and updating these tools regularly as designs evolve. Balancing efficiency and quality in aerospace fixtures is an ongoing struggle in the industry.

Aerospace fixtures play a crucial role in aircraft manufacturing. These tools ensure precision during assembly and inspection. By holding components securely, they reduce movement that could lead to errors. This stability increases overall safety and reliability in aerospace products.

Understanding aerospace fixtures involves recognizing their varied designs. Each fixture caters to specific components, like fuselages or wings. They often appear complex, but their purpose is straightforward. A well-designed fixture minimizes human error. However, creating them requires extensive testing and iteration.

In the manufacturing process, flaws can arise. Some fixtures may not fit perfectly or hold parts as needed. This could lead to delays or costly adjustments. Manufacturers must constantly evaluate and refine these tools. Regular feedback is essential for innovation and improvement in aerospace technology.

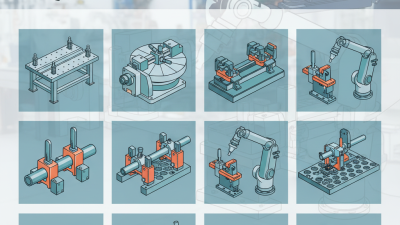

| Fixture Type | Definition | Importance | Material Used | Applications |

|---|---|---|---|---|

| Assembly Fixtures | Devices that hold and align parts for assembly operations. | Ensures precision and reduces assembly time. | Aluminum, Steel | Wing assembly, fuselage joining |

| Testing Fixtures | Frames designed to hold components during testing. | Facilitates accurate testing and validation of components. | Composite materials, High-strength steel | Engine tests, structural integrity tests |

| Inspection Fixtures | Tools for holding parts during the inspection process. | Ensures components meet quality standards. | Steel, Plastic | Quality control, compliance checks |

| Welding Fixtures | Hold parts in position during welding processes. | Ensures joint accuracy and strength. | Metal, Fiber-reinforced composites | Body frame welding, structural assemblies |

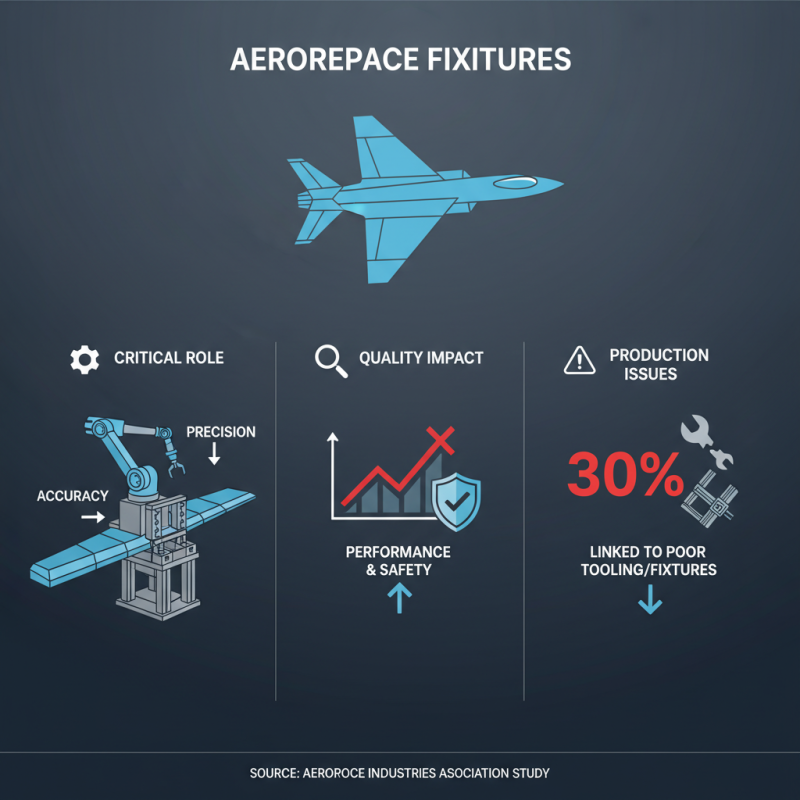

Aerospace fixtures play a critical role in aircraft manufacturing processes. These fixtures are essential for ensuring precision and accuracy in complex assembly tasks. The quality of fixtures influences the final product's performance and safety significantly. In fact, a study by the Aerospace Industries Association reveals that up to 30% of production issues are linked to poor tooling and fixtures.

The importance of aerospace fixtures is evident in assembly line efficiency. For instance, manufacturers report that well-designed fixtures can reduce assembly time by up to 20%. This reduction in time directly correlates with cost savings and productivity increases. However, not all fixtures are perfect. There can be design flaws that lead to rework, adding unexpected delays. Regular assessments of fixture performance are needed to identify these opportunities for improvement.

When it comes to quality control, fixtures must be adaptable. The aerospace sector is evolving, with new materials and designs emerging constantly. A report by the National Institute of Standards and Technology states that innovative fixtures are critical for integrating new technologies efficiently. Yet, there remains a challenge in quickly adapting existing fixtures to accommodate these advancements. Continuous training for personnel on the latest techniques is vital.

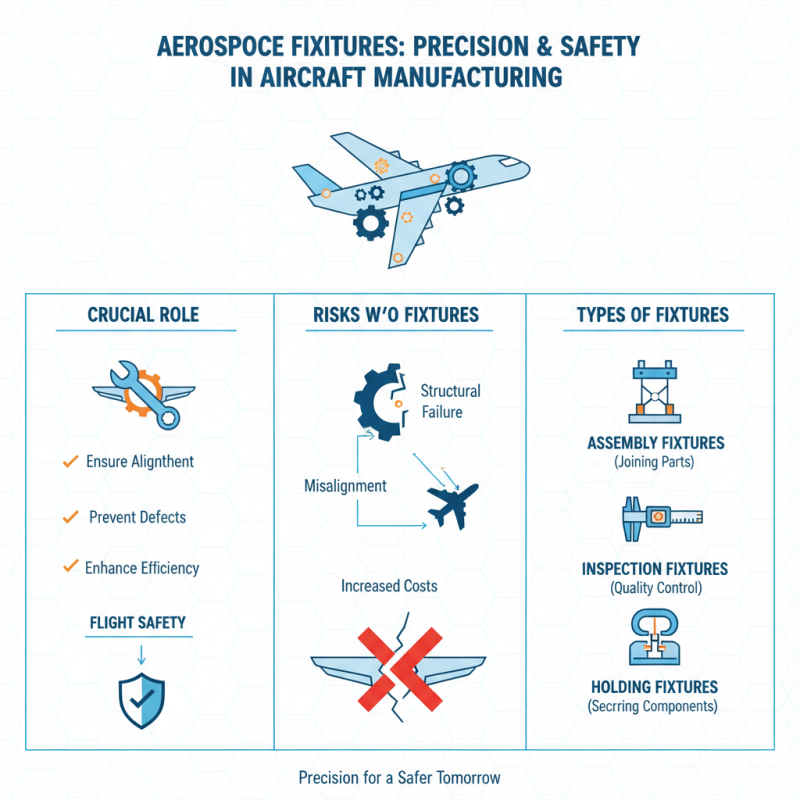

Aerospace fixtures play a crucial role in aircraft manufacturing. They ensure precision and safety throughout the assembly process. Without these fixtures, the risks of misalignments increase, leading to potential failures in flight. Various types of fixtures serve distinct purposes in the industry.

One key type is the assembly fixture. It holds components in place during assembly. These fixtures allow workers to focus on tasks without worrying about stability. Another type is the inspection fixture, which ensures that each part meets stringent quality standards. These fixtures are essential for compliance with safety regulations.

In addition to assembly and inspection, tooling fixtures aid in machining processes. They help define the exact shape and size of aircraft components. However, creating effective fixtures is often challenging. Designers must balance speed, cost, and functionality. Mistakes in fixture design can lead to delays and increased costs. The journey to perfecting aerospace fixtures is ongoing, with many lessons learned through trials and errors.

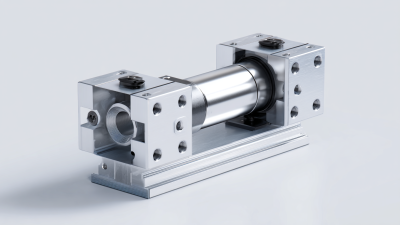

Aerospace fixtures play a crucial role in aircraft manufacturing. These specialized tools ensure precision in every component. They allow for accurate placement of parts, leading to enhanced quality. Manufacturing involves complex materials and designs. Therefore, the right fixture makes a significant difference.

Utilizing aerospace fixtures optimizes the production process. They reduce the chances of errors during assembly. A small mistake can lead to major issues later. Fixtures also improve worker efficiency. With standardized tools, employees spend less time adjusting components. Instead, they can focus on quality checks and other tasks.

However, it's important to consider the design of these fixtures. Not all fixtures are created equal. Some may not fit specific needs and could cause delays. Regular evaluation and adjustment of fixtures are crucial. This reflective process ensures they meet the evolving demands of aerospace technology. In the end, the careful use of specialized fixtures fosters excellence in aircraft manufacturing.

Aerospace fixtures play a pivotal role in aircraft manufacturing. These tools ensure precision during assembly. However, creating effective fixtures is often challenging. Designers face difficulties in adapting to constantly changing aircraft designs. As technology evolves, so do the requirements.

Innovations in materials can contribute to better fixtures. Lightweight options allow for easier handling. Yet, these materials may lack the strength needed for heavier components. Finding the right balance is crucial. Additionally, automation presents new opportunities. Robotic systems can enhance precision but require well-designed fixtures.

Despite advancements, there are gaps in current designs. Some fixtures become outdated quickly. Regular evaluations are necessary to keep pace with innovations. Collecting feedback from the assembly team offers insights for improvement. Understanding these challenges can lead to better solutions and innovations in aerospace fixture design.