Aerospace Fixtures are critical components in the aviation industry. They ensure precision during manufacturing and assembly processes. According to a recent report by the Aerospace Industries Association (AIA), the global aerospace fixtures market is projected to grow by 8% annually, reflecting rising demand.

Expert James Carter, a leading figure in aerospace manufacturing, states, "Aerospace Fixtures are the backbone of quality control." His insights underline the importance of reliable fixtures in maintaining safety and efficiency in aircraft production.

Yet, the industry faces challenges. Many companies struggle with outdated tools. This can lead to inefficiencies. Moreover, a lack of investment in modern fixtures could hinder innovation. As the aerospace sector grows, adapting to these changes remains vital. The future depends on improving Aerospace Fixtures for better safety and performance.

Aerospace fixtures play a crucial role in the aviation industry. They are specialized tools that hold, support, and secure aircraft components during various processes. This includes manufacturing, assembly, and maintenance. A well-designed fixture ensures precision and consistency in these critical operations. It helps in meeting stringent safety standards and enhancing performance.

These fixtures can vary in complexity. Some are simple jigs for holding parts, while others are highly advanced systems integrated with automation. The importance of aerospace fixtures cannot be overstated. They reduce assembly time and minimize errors, leading to higher productivity.

**Tips:** Ensure your fixtures are regularly inspected. Wear and tear can impact accuracy. Keep your workspace organized to prevent mistakes. Simple changes can have significant benefits.

In aerospace, every detail matters. Improperly designed fixtures can lead to costly reworks. Investing time in design and testing pays off in long-term reliability. Consider engaging teams in brainstorming sessions to improve fixture design. Collaborative efforts often reveal hidden issues and innovative solutions.

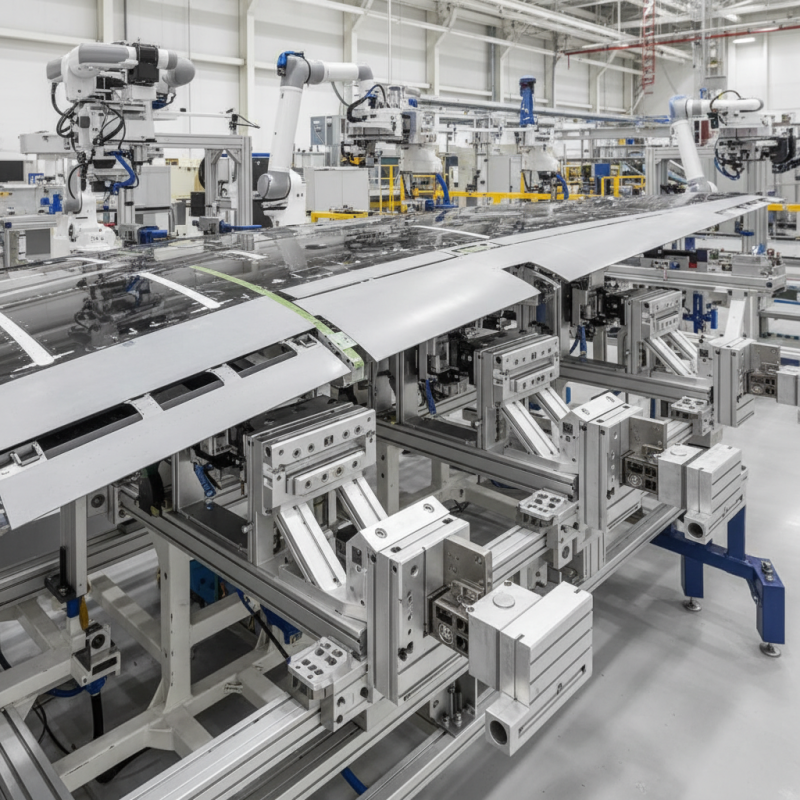

Aerospace fixtures are essential tools in the aviation industry. They hold and support aircraft components during assembly, maintenance, and repair. There are several types of aerospace fixtures that meet specific needs in aviation.

One common type is assembly fixtures. These tools align parts accurately for welding or fastening. They ensure precision in the manufacturing process. A report from the Aerospace Industries Association revealed that proper alignment reduces errors by 25%. This statistic highlights the importance of high-quality fixtures.

Another notable type is test fixtures. They are used to evaluate component performance under various conditions. These fixtures help simulate flight conditions for safety assessments. According to a recent study, 30% of aircraft failures occur due to insufficient testing. Test fixtures can significantly mitigate this risk.

There are also storage fixtures, which organize components during production. This can minimize the risk of damage and loss, but these setups often face challenges. Maintaining an organized system is difficult amidst a busy workflow. Continuous reflection on these processes is vital to improve efficiency in aviation operations.

| Fixture Type | Description | Importance | Common Applications |

|---|---|---|---|

| Assembly Fixtures | Used to hold components together during assembly | Ensures accuracy and consistency in assembly processes | Airframe assembly, engine assembly |

| Inspection Fixtures | Used for the precise measurement and inspection of parts | Helps in maintaining quality control and compliance | Component quality checks, dimensional inspections |

| Welding Fixtures | Used to hold and support parts during welding | Enhances stability and reduces deformation during welding | Structure welding, component joins |

| Tooling Fixtures | Designed to hold tools in a fixed position | Increases accuracy and reduces setup time | Machining operations, cutting tasks |

| Transport Fixtures | Used for safe transportation of components | Protects parts from damage during handling and transport | Component shipping, handling |

Aerospace fixtures play a vital role in the aviation industry. They are essential tools that support the manufacturing and assembly of aircraft. These fixtures ensure precision, enhance efficiency, and maintain safety standards.

According to a recent industry report, well-designed aerospace fixtures can increase production efficiency by up to 25%. This increase translates to faster turnaround times and reduced costs.

The benefits of aerospace fixtures extend beyond just production efficiency. They help to minimize human error during the assembly process. Precise alignment and secure placements lead to higher quality control.

However, some fixtures can become outdated or require adjustments over time. It’s crucial to evaluate and refine these tools continually. In fact, 40% of aerospace manufacturers reported challenges in adapting to new technologies, which can impact fixture design and efficiency.

Moreover, aerospace fixtures are pivotal for compliance with safety regulations. The industry mandates strict adherence to safety guidelines. Each fixture must consistently meet these standards, yet many companies struggle with maintaining compliance.

Regular audits and updates are necessary, but they can be resource-intensive. The industry should focus on developing more adaptable and intelligent fixtures to streamline this process.

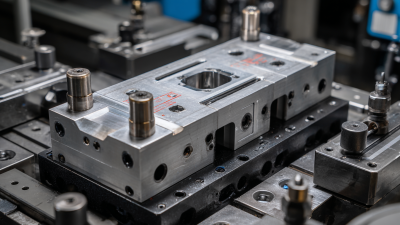

Aerospace fixtures play a pivotal role in the aviation industry. They ensure accuracy and safety during production and assembly processes. The right materials can make a significant difference. Typically, lightweight materials like aluminum and composites are preferred for aerospace fixtures. These materials reduce overall weight while maintaining strength.

For instance, a report from the International Journal of Aerospace Engineering highlights that aluminum fixtures reduce manufacturing costs by about 30%. However, not all aerospace manufacturers prioritize material selection. Some still use heavier materials, leading to inefficiencies. Such choices can compromise the structural integrity of components.

Manufacturing processes also impact fixture effectiveness. CNC machining is common, but can be resource-intensive. It may not always yield precise results. In contrast, additive manufacturing offers flexibility but may fall short in durability under certain conditions. Rethinking these choices is essential for better performance. The industry must focus on continuous improvement to optimize fixture design and production methods.

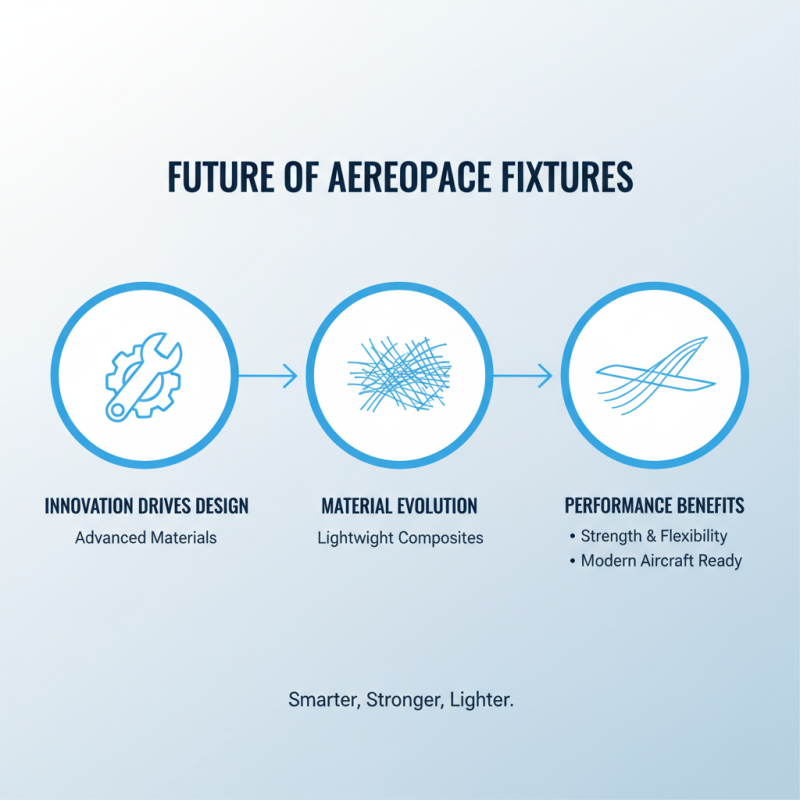

The future of aerospace fixtures is about innovation. Manufacturers are exploring advanced materials. Lightweight composites are gaining popularity. They offer strength and flexibility, vital for modern aircraft.

Automation is another key trend. Robotics and AI streamline the production process. These technologies can enhance precision and reduce human error. Yet, the reliance on machines introduces challenges. Workers must adapt to evolving roles. Training programs are critical.

Sustainability also drives change. Eco-friendly manufacturing practices are emerging. The industry faces pressure to minimize waste. However, while some solutions are promising, others are still experimental. Balancing innovation with existing safety standards is essential. Future fixtures must not compromise reliability for novelty.