In the aerospace industry, precision is crucial. Aerospace Fixtures play a vital role in achieving this precision. These tools are designed to hold and support aircraft components during manufacturing and assembly. They ensure that each part is positioned correctly.

The benefits of Aerospace Fixtures extend beyond mere support. They enhance efficiency and reduce the risk of errors. With a steady grip on components, these fixtures allow workers to focus on their tasks without worrying about misalignment. This is especially important in high-stakes environments where accuracy can mean the difference between success and failure.

However, the design of Aerospace Fixtures is not without challenges. Creating a fixture that is both versatile and robust can be difficult. Companies must constantly evaluate their designs to improve performance. Thus, while Aerospace Fixtures offer significant benefits, they also require ongoing reflection and refinement.

Aerospace fixtures are specialized tools used to hold and support components during manufacturing processes. They ensure precision and accuracy in assembly and machining operations. According to recent industry reports, effective fixtures can reduce assembly times by up to 30%. This significant improvement boosts overall efficiency in production lines.

Understanding aerospace fixtures involves recognizing their design and function. These fixtures vary widely in complexity. Some are tailored for specific components, while others can accommodate multiple parts. The challenge lies in balancing versatility with precision. A poorly designed fixture may lead to inconsistencies in production quality. Around 20% of defects in aerospace components can be traced back to inadequate fixturing.

Industry experts note that advancements in materials, such as lightweight composites, further enhance fixture performance. However, such innovations come with a cost. The investment in high-quality fixtures may not always yield immediate returns. Companies must continuously assess their fixture strategies to ensure optimal results. The right fixture can make a substantial difference, but not every solution fits every need.

Aerospace fixtures play a crucial role in manufacturing and assembly processes. They ensure precision and consistency across various aerospace components. There are several types of fixtures used in the industry, each serving specific functions.

One common type is assembly fixtures, which are vital for aligning and fastening parts accurately. They help reduce human errors, thus increasing efficiency. According to a recent industry report, the use of advanced assembly fixtures can enhance production speed by up to 25%. This is significant, especially when timelines are tight.

Another type is welding fixtures. They assist in holding parts in place during the welding process, ensuring quality and precision. Data shows that properly designed welding fixtures can decrease rework rates by as much as 30%. However, the challenge lies in designing fixtures that accommodate various part geometries and materials. Engineers often need to balance between versatility and specificity.

Despite the clear benefits, some fixtures may not fully meet production needs. Continuous evaluation helps improve their designs. Understanding the evolving dynamics within aerospace manufacturing is essential for optimizing fixture use and enhancing overall productivity.

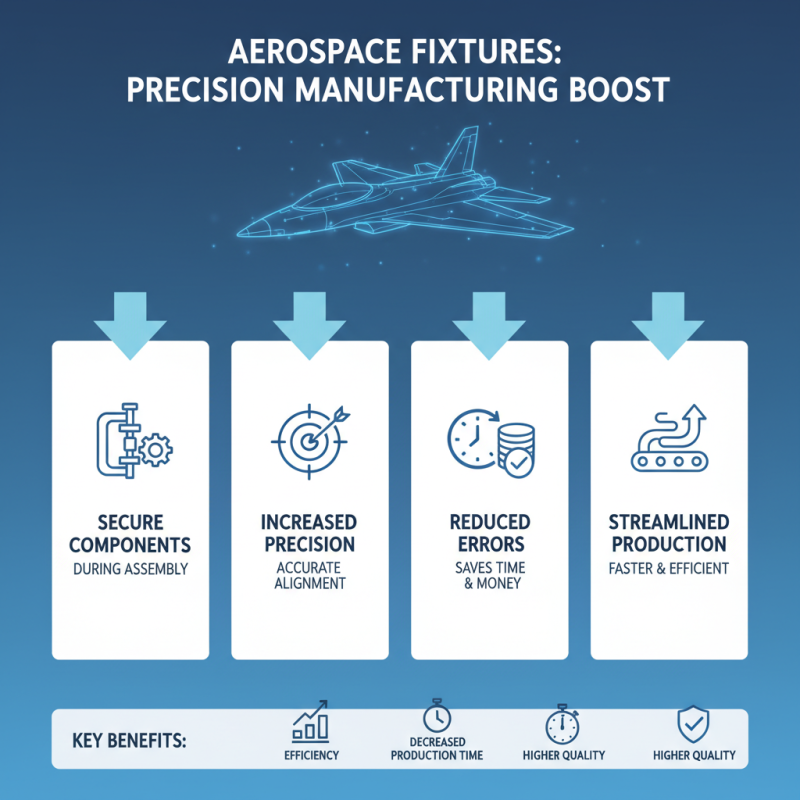

Aerospace fixtures play a crucial role in the manufacturing process. They help secure components during assembly. This leads to increased precision. Accurate alignment reduces errors. Reducing mistakes saves time and money. Pathways for manufacturing become more streamlined. Efficiency rises, and production times decrease.

Another key benefit is flexibility. Aerospace fixtures can adapt to a range of parts. This versatility supports diverse manufacturing needs. Manufacturers can quickly switch between projects. However, not all fixtures are created equal. Some may require regular modifications, which can be a challenge.

Durability also stands out in aerospace fixtures. They withstand harsh conditions. This resilience ensures longevity and reliability. Nonetheless, the initial investment can be significant. It often raises questions about long-term worth. Over time, proven fixtures usually justify their costs. Their benefits typically outweigh initial financial concerns.

When designing aerospace fixtures, several critical considerations come into play. Precision is paramount. Fixtures must accommodate various aircraft components with exact tolerances. A deviation of even a few millimeters can result in significant issues during assembly. Materials used should withstand extreme conditions, including temperature fluctuations and corrosion. Aluminum and composite materials often serve as popular choices.

Another essential factor is ease of use. Fixtures need to be intuitive for operators. Complicated setups can lead to errors and inefficiencies. The design should enable quick adjustments and clear alignment markings. This will save time and reduce frustration.

On the other hand, it's important to regularly review and refine fixture designs. What works today may not be optimal tomorrow. Feedback from users is crucial for continuous improvement.

Additionally, consider the environmental impact of fixtures. Sustainable materials and processes should be prioritized. However, achieving this can be challenging, as eco-friendly materials sometimes lack the required durability. Balancing performance with sustainability is an ongoing dilemma. It demands innovative thinking and a willingness to adapt. Overall, effective aerospace fixture design involves many moving parts, requiring careful thought and reflection.

The landscape of aerospace fixture technology is rapidly evolving. Innovations such as lightweight materials and modular designs are at the forefront. Aerospace engineers are exploring advanced composites that reduce weight while maintaining strength. This shift could enhance aircraft efficiency and fuel economy significantly.

Digital fabrication methods, like 3D printing, open new possibilities. Custom fixtures can be designed and produced rapidly, reducing lead times. However, there are challenges. This technology requires precise calibration and quality control. If not managed well, it could lead to inconsistencies in production.

Sustainability is a key consideration. Manufacturers are assessing material sources to minimize environmental impact. Using recycled materials can be both an ambition and a hurdle. Many companies still face difficulties in assimilating sustainable practices. Balancing innovation with responsibility remains an ongoing concern in the aerospace sector.