In today's competitive manufacturing landscape, accurate CMM measurement is crucial for quality control. According to a report by the International Organization for Standardization (ISO), over 30% of manufacturing defects stem from measurement errors. Ensuring precision in CMM measurement directly affects product quality and customer satisfaction.

Industry expert Dr. John Smith states, “CMM measurement is not just a process; it's a cornerstone of quality assurance.” This underscores the importance of precision in measurement techniques. Failure to implement accurate CMM methods can lead to significant setbacks, costing companies both time and money.

Yet, many organizations struggle with inconsistencies in their measurement processes. Training and regular calibration are often overlooked. As a result, the potential for errors remains high, highlighting the need for continuous improvement in CMM measurement standards. Quality control is an ongoing journey, not a destination.

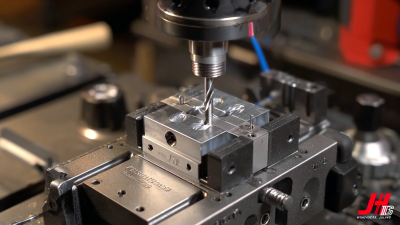

CMM (Coordinate Measuring Machine) measurement is crucial for quality control in manufacturing. To ensure accuracy, it's essential to understand the underlying principles of CMM measurements. A CMM uses a probe to touch the surface of an object. It gathers precise data about the object's geometry. This data allows engineers to assess conformity to design specifications. However, even the best equipment can yield errors if not operated correctly.

Tips: Regularly calibrate your CMM. Calibration can significantly impact measurement accuracy. A well-calibrated machine provides reliable data. Be vigilant about environmental factors as well. Temperature and humidity can affect readings. Ensure your workspace remains stable.

Understanding CMM principles includes mastering probe selection and movement speeds. Different probes work for various materials. The right probe helps minimize measurement errors. Slow and steady movement often yields better results. Quick measurements can introduce inconsistencies. Always analyze your data thoroughly. Look for patterns or anomalies that may indicate equipment issues or operator error. Reflect on your measurement practices. Improvement is always possible.

| Measurement Component | Measurement Value (mm) | Tolerance (mm) | Status |

|---|---|---|---|

| Length of Component A | 50.05 | ± 0.10 | Pass |

| Diameter of Component B | 25.00 | ± 0.05 | Pass |

| Height of Component C | 75.10 | ± 0.15 | Fail |

| Thickness of Component D | 10.02 | ± 0.02 | Pass |

| Angle of Component E | 45.00 | ± 0.5 | Pass |

Choosing the right CMM (Coordinate Measuring Machine) equipment is essential for achieving precise measurements in quality control. There are several types of CMMs available. Each type serves different purposes. A bridge-style CMM is versatile. It can measure both large and small parts effectively. However, it may not be suitable for very complex shapes.

Portable CMMs offer flexibility. They allow for measurements in various locations. This convenience can be advantageous, but portability might compromise accuracy. Additionally, some portable devices struggle with repeatability. These challenges require careful consideration during equipment selection.

The probe type is also critical. Touch probes provide high precision, but they can be slower. On the other hand, laser probes offer speed but may lack the same accuracy on textured surfaces. Balancing speed and accuracy is key. Before deciding, it's worth testing different options.

Each machine’s capabilities should align with your specific needs and measurement tasks. An improper choice can lead to measurement errors and wasted resources. Take your time evaluating options.

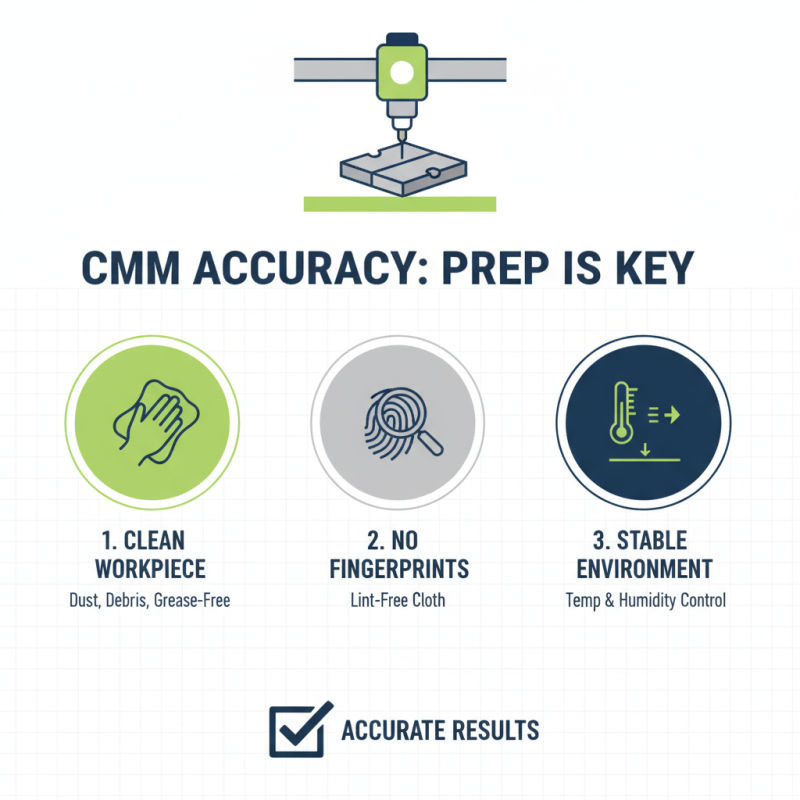

Preparing the workpiece and environment for CMM measurement is crucial for achieving accurate results. Start by ensuring the workpiece is clean. Dust and debris can lead to measurement errors. Using a lint-free cloth, wipe down surfaces meticulously. Make sure the part is free of grease or oil. Even fingerprints can affect precision.

The environment should be stable and controlled. Temperature fluctuations can cause materials to expand or contract. Ideally, the workspace should be temperature regulated. Humidity can also play a role; too much moisture can affect the machine's readings. Consider placing the CMM in a dedicated room away from drafts.

Check the setup before beginning measurements. Verify that the CMM is properly calibrated. Taking extra time to calibrate can save you from inaccurate readings later. Once you start measuring, pay attention to any deviations. Reflect on any inconsistent results. Small mistakes in preparation can lead to larger quality control problems down the line.

Performing accurate CMM measurements is essential in quality control. Follow a step-by-step procedure to ensure precision. Start by preparing the workpiece. Clean it thoroughly to remove any contaminants. Position it securely on the measurement platform. Check that the environment is stable. Size and temperature matter in achieving reliable results.

Next, calibrate the CMM before use. Ensure the probe is functioning properly. A simple check can prevent larger issues down the line. Define the measurement strategy clearly. Decide on the points to measure, such as edges and surfaces. Document this plan to avoid confusion later.

Finally, conduct the measurements carefully. Take multiple readings to verify data accuracy. Analyze the results with a critical eye. Anomalies may indicate deeper issues with the part. Reflect on any discrepancies you find. This process helps improve future measurements and enhances product quality. Each step builds upon the last, leading to consistent results.

Interpreting CMM data is critical for quality assurance in manufacturing. A CMM or coordinate measuring machine gathers precise measurements of a part's dimensions. However, the data must be analyzed thoroughly to ensure validation. At times, operators may overlook minor deviations. Such oversights can lead to significant quality issues.

It's essential to evaluate trends in the data. For example, a gradual shift in measurements may indicate wear in the machinery or misalignment in setups. Operators must be vigilant. Highlighting anomalies can guide corrective action before more extensive problems arise. Don't shy away from questioning the data. What does a clustered data point reveal? Sometimes, a closer inspection uncovers serious fabrication errors.

Documentation plays a vital role in communication with the quality control teams. Observations on data inconsistencies are as important as the measurements themselves. Human error can creep in during data recording. It's crucial to maintain accuracy. Review processes may need to be adjusted frequently based on findings from measurement analyses. Continuous improvement is necessary for sustaining quality standards.